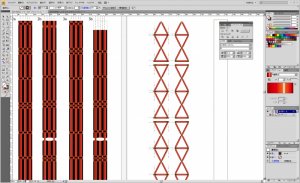

The Oaska 1970 Expo Tower (which served as design inspiration for the Valley Forge) was still standing till 2006... I think.

http://park2.wakwak.com/~ichiro/r3/p615/r3p615img/expo020518.jpg

http://www.antonraubenweiss.com/expo/webimages/osaka07.jpg

Scroll way down on this page)

20th Century Boys Encyclopedia: Osaka World Expo 1970

Maybe some useful details there?

http://park2.wakwak.com/~ichiro/r3/p615/r3p615img/expo020518.jpg

http://www.antonraubenweiss.com/expo/webimages/osaka07.jpg

Scroll way down on this page)

20th Century Boys Encyclopedia: Osaka World Expo 1970

Maybe some useful details there?