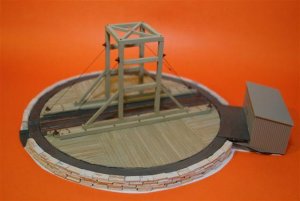

I model the Montana Western Rwy (circa 1948-50)... which was small feeder line that served the GN, and had two small lokeys and one gas-electric. I wanted to have a prototypical Laws type covered turntable to just turn the engines, as they only had a two stall engine shed that didn't require a T/T for that function.

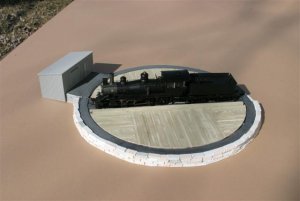

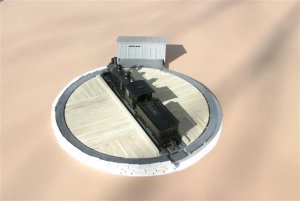

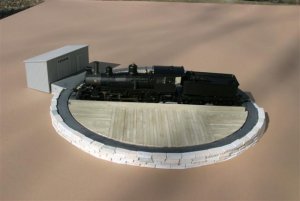

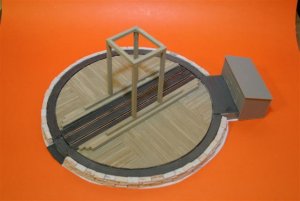

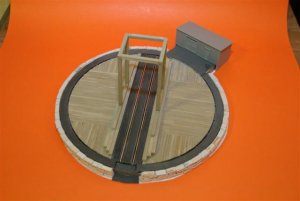

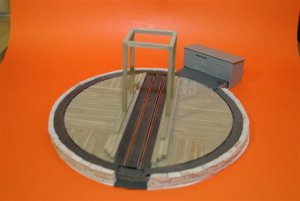

The Atlas HO table is nicely engineered, but it is not the best looking piece of equipment.. so I decided to try my hand at bashing the little Atlas... I first wanted to lay a wood deck made of driftwood stained stripwood, and then add styrene "diamond pattern" steel deck plate walkways, and track area. Next I wanted to add a stone wall around the perimeter of the deck & walkway. I have the stone wall half finished, and when that is completed I will add the Laws framework (timbers & anchor chain devices), and finally a scratchbuilt supply shed to house the T/T motor (as the Atlas shed can certainly be improved upon).

I would appreciate any critique comments... Bob

The Atlas HO table is nicely engineered, but it is not the best looking piece of equipment.. so I decided to try my hand at bashing the little Atlas... I first wanted to lay a wood deck made of driftwood stained stripwood, and then add styrene "diamond pattern" steel deck plate walkways, and track area. Next I wanted to add a stone wall around the perimeter of the deck & walkway. I have the stone wall half finished, and when that is completed I will add the Laws framework (timbers & anchor chain devices), and finally a scratchbuilt supply shed to house the T/T motor (as the Atlas shed can certainly be improved upon).

I would appreciate any critique comments... Bob