Walk / duck under.....

- Thread starter Conrail

- Start date

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

I have a pair. (See my thread on spline roadbed). One of them goes over the bottom of the stairs, the other across the laundry room doors.

After 2 years, I am used to it. When it's removed, we still duck down.

It has given me a continuous run and I seem to run trains more -- get the locos up to speed. I think it's probably worth it. :thumb:

After 2 years, I am used to it. When it's removed, we still duck down.

It has given me a continuous run and I seem to run trains more -- get the locos up to speed. I think it's probably worth it. :thumb:

duck under

I had a 7 1/2' X 24' layout with one side against a wall, with an 18" space down the middle. That meant ducking down every time I needed to get to the back part. I got a thick sponge rubber mat to crawl on, which made it a bit easier. When it got to where it took longer for me to stand up than it did to crawl, I tore it all apart. I now have a 5' X 20' , and can easily reach any part from the sides. NEVER again a duck under.

Lynn

I had a 7 1/2' X 24' layout with one side against a wall, with an 18" space down the middle. That meant ducking down every time I needed to get to the back part. I got a thick sponge rubber mat to crawl on, which made it a bit easier. When it got to where it took longer for me to stand up than it did to crawl, I tore it all apart. I now have a 5' X 20' , and can easily reach any part from the sides. NEVER again a duck under.

Lynn

S

stashu45

I just started my layout 8 1/2ft by 26 1/2ft a year ago with a 30 inch wide section running down the center. On a good day the duck under is ok on a bad day when I get down on the floor I say to myself "is there anything else I should down here before I stand up?". But that is the price you pay when the layout has two sides against the wall and you want continuous running and not "U" shaped.

I was just curious because my new layout is "U" shaped with three sides against the wall. I was thinking of maybe running a second indepent oval around the top of the hillside I'm planning then add a nice bridge of some sort to span over the walk way into the "U" (approx 29"). I think it would probably be up about 67-69" from the floor which would put it just about level with my nose. I'm just wondering how many times I will forget to duck and tear the bridge down before I start remembering.

duck

That's easy enough to remedy. Merely put a 2X4 across in front of it. Once or twice hitting it and you'll remember to duck.

Lynn

That's easy enough to remedy. Merely put a 2X4 across in front of it. Once or twice hitting it and you'll remember to duck.

Lynn

I will be using a duck under across the door on my round the walls layout.IMHO that is the simplest solution for me.

yellowlynn said:That's easy enough to remedy. Merely put a 2X4 across in front of it. Once or twice hitting it and you'll remember to duck.

Lynn

Ha Ha

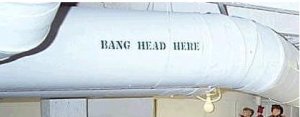

I have a similar problem with a HVAC duct. I added a note just to make sure I didn't miss it.Conrail said:Ha HaThat seriusly is a good idea though. Just put up a piece of scrap 2x4until I get in the habbit of ducking down and then remove it.

Doc

Attachments

To me, totally depends on layout height. I had a layout about 40" high with a "crawl" under and hated it. Next layout was 60" high with a true "duck" under and had no problem with it... Layout I'm planning right now will almost certainly have a duck under, again the layout will sit rather high, though.

Duck under here

and if you want something bigger than a duck under there, we can supply you with a surplus Canada Goose (or a hundred).

and if you want something bigger than a duck under there, we can supply you with a surplus Canada Goose (or a hundred).

A duckunder is ok as long as you're able to duck under it. Had one on a previous layout and it posed no problem. However, in those days I was quite a bit more flexible than I am now. If you're reasonably young, you won't really appreciate this 'til later. On my current layout, I have a lift-out/duck-under at the door: on a good day, it's a duck-under; most of the time its a lift-out. It's just a single track, curved, with no scenery. It provides access to a staging track and also allows run through operations when I just want to run trains for casual visitors. I used flex track on 3/4" plywood and provided very positive and rigid alignment for the ends of the plywood. Lay the track continuously from the layout on one side, across the plywood, and onto the other side. Spike the track down securely and then, using the small spikes that are used for hand-laying track, spike both sides of each rail, on both ends of the removeable section and likewise on each end of the fixed section for at least three ties (pre-drill the ties first), taking care to not push anything out of alignment. Cut the rails with a cut-off disc in a Dremel tool, staggering the cuts if the track is on a curve and making sure that the fixed (layout) portion is back from the edge. The ends of the rails on the lift-out should project beyond the end of the plywood. After the rails have been cut, you may have to reposition the small spikes that hold the rails in line - you don't want the projecting end of the rails on the lift-out to be spiked to the layout. When everything is satisfactory, use a sharp knife to cut the ties at a point directly above the joints between the layout and the lift-out. On a curve,this may put part of a tie on the lift-out and part on the layout. Spike any such ties near the cut ends using the small spikes. Now you should be able to carefully lift out (straight up) the removeable section. The recessed ends of the track on the layout will protect them but the track ends on the lift-out are vulnerable and this section should be stored accordingly when not in use. I used a small plug from Radio Shack to provide power to the lift-out, female part on the layout edge, male part on a wire from under the lift-out. This contraption has been in use with very little attention for over ten years. Hope this is of some assistance.