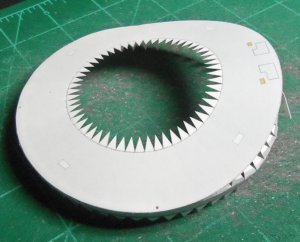

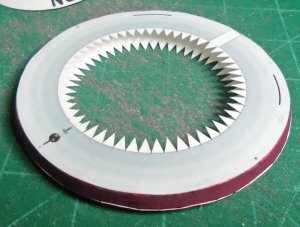

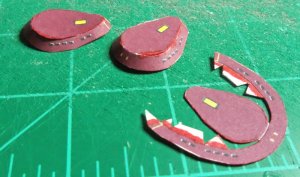

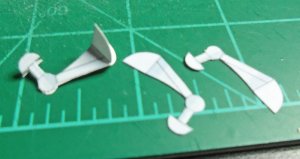

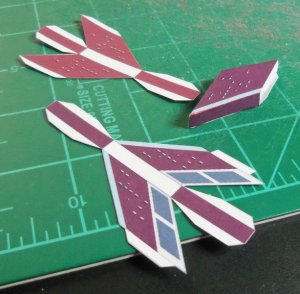

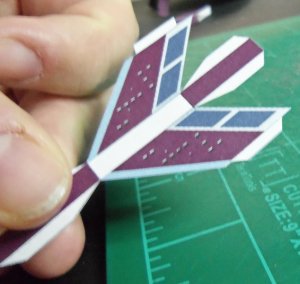

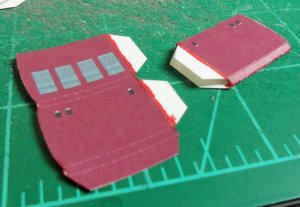

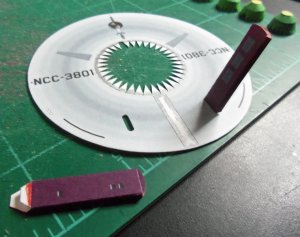

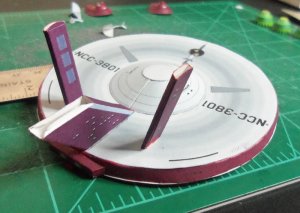

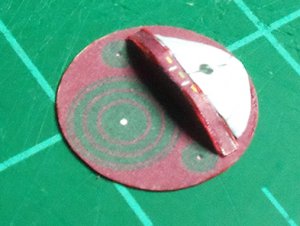

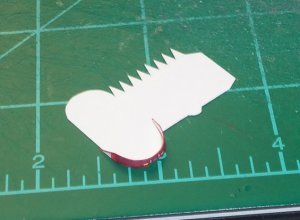

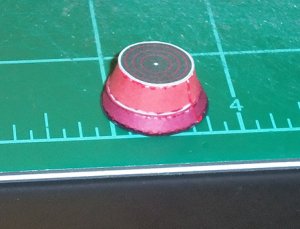

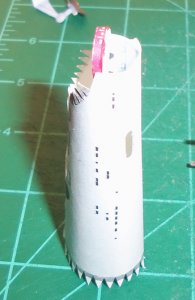

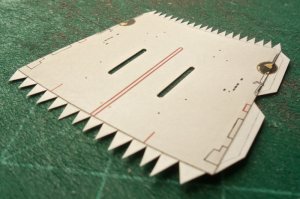

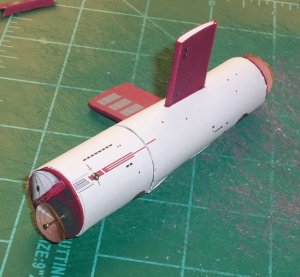

Well, what do you do when you start building a bunch of Starfleet ships? Start building Mirror Universe ships, of course! With all the Connies complete and more Starfleet ships being built, I've decided it's time to add some of my favorite villains. Again, these are my repaints of Rawen's original, fantastic files. I am building my versions of an Empire Heavy Cruiser (I.S.S. Predator), Dreadnought (I.S.S. Worldbreaker), Destroyer (I.S.S. Godhammer) and Tug (I.S.S. Scow).

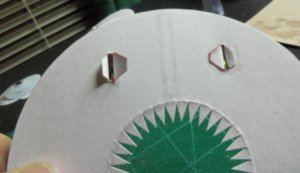

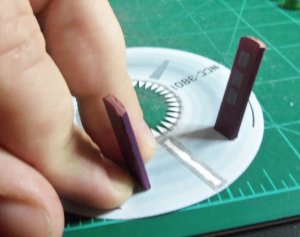

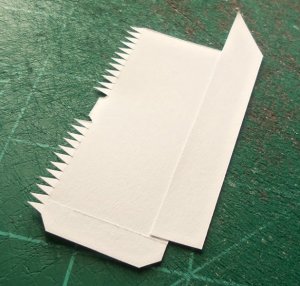

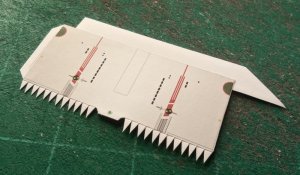

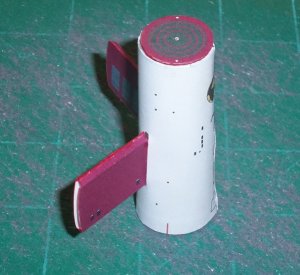

I am building all four ships at once so my post will skip around a little, but my goal is to show a detailed buildup of these Rawen ships for reference. My technique is by no means perfect, but it's worked well for me and may work even better for someone with more steady hands. Sorry if the post gets a little long, but I'm a writer and used to presenting all the data. I'll try to keep it under control.

FYI, sometimes I forget to take a pic, so if you see a part change around ignore it since I'm just trying to show my technique.

I am building all four ships at once so my post will skip around a little, but my goal is to show a detailed buildup of these Rawen ships for reference. My technique is by no means perfect, but it's worked well for me and may work even better for someone with more steady hands. Sorry if the post gets a little long, but I'm a writer and used to presenting all the data. I'll try to keep it under control.

FYI, sometimes I forget to take a pic, so if you see a part change around ignore it since I'm just trying to show my technique.