This morning, I went to my local hardware store. While I was walking around. I saw some solder paste with flus in it. "What a good idea to use for soldering track!" I thought. I tried it and was very impressed!

Here's what I did. I cleaned the rail joiner and end of the track. I applied a little bit of paste on the end of the rail and in the channel of the joiner. I then used my 30 watt soldering iron and heated the rail. DO NOT lay the iron on the solder paste! Once the paste starts to bubble, remove the iron. Whipe clean with a damp clothe. I found soldering the track in sections of 2 was best.

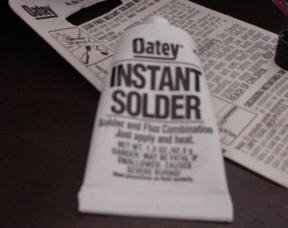

Here's some pictures of my work.

Andy

Here's what I did. I cleaned the rail joiner and end of the track. I applied a little bit of paste on the end of the rail and in the channel of the joiner. I then used my 30 watt soldering iron and heated the rail. DO NOT lay the iron on the solder paste! Once the paste starts to bubble, remove the iron. Whipe clean with a damp clothe. I found soldering the track in sections of 2 was best.

Here's some pictures of my work.

Andy