Hello there, it's me again! The TrainClown with many hats!

I know this is a little off the topic of trains but I have this idea in mind that the same process that I use to fix my van would also be a good way to make scenery for garden layouts. Mountains, cliffs, tunnel culverts, etc., could be made using the same process that I used to fix gaping rust holes in my van. So I thought I would share this information, for what it is worth, and maybe someone would see the germ of an idea for their own projects.

I used to call my van Snaggletooth because of all the rusted out quarter panels which gave it a decidedly toothy snarl and, no sir, I didn't like it. So earlier this summer I set about fixing it and this is how it went.

I'm not going to show you the whole project, just one little part to show you the secrets I have gained over the years.

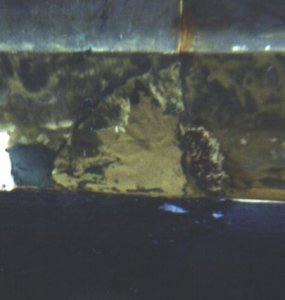

This first photo shows you the typical problem of the giant rust hole in the back corner of the van.

I know this is a little off the topic of trains but I have this idea in mind that the same process that I use to fix my van would also be a good way to make scenery for garden layouts. Mountains, cliffs, tunnel culverts, etc., could be made using the same process that I used to fix gaping rust holes in my van. So I thought I would share this information, for what it is worth, and maybe someone would see the germ of an idea for their own projects.

I used to call my van Snaggletooth because of all the rusted out quarter panels which gave it a decidedly toothy snarl and, no sir, I didn't like it. So earlier this summer I set about fixing it and this is how it went.

I'm not going to show you the whole project, just one little part to show you the secrets I have gained over the years.

This first photo shows you the typical problem of the giant rust hole in the back corner of the van.