I'm trying to put together a 3 loco set to pull a longer train comprised of Life-Like N scale F7's. In running the pair together last night and having some coupler issues, the two became separated. It is plain that one is much faster at the same throttle setting than the other. Is there any way to correct this? (I'm guessing probably not) Will this cause damage to either loco if they are run connected in this fashion? (I'm guessing yes) Is there any other solution aside from getting a few more chassis and finding a couple that are close?

Disproportionate loco speeds

- Thread starter ddavidv

- Start date

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

If you are running DCC, you can tune the decoder to provide the same speed in all three locos. With DC, match them up as best you can with the faster loco at the front.

Here are a few discussions on the topic:

http://www.the-gauge.com/thread15174-running-paired-engines.html

http://www.the-gauge.com/thread14919-dcc-question.html

http://www.the-gauge.com/thread4284-beginners-help-with-multiple-locos.html

Andrew

Here are a few discussions on the topic:

http://www.the-gauge.com/thread15174-running-paired-engines.html

http://www.the-gauge.com/thread14919-dcc-question.html

http://www.the-gauge.com/thread4284-beginners-help-with-multiple-locos.html

Andrew

If you are running LL N scale F7's, I'm gunna say that you are not running DCC. I have a few more than several LL geeps and that's a problem you will not easily overcome using DC. I haven't done this, but might give it a try someday, and that is to try to lower the voltage to the fastest locos to match the speed of the slowest one. The first thing I would try would be to put a resistor in series with the motor in hopes of getting a slight voltage drop across it. What value and wattage resistor? I haven't a clue until I try it, but I'd say under 100 ohms and maybe 1/2 watt would do. The only way to find out is by trial and error. What would be good for one loco wouldn't work on another.

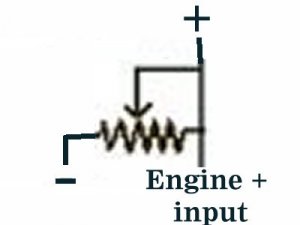

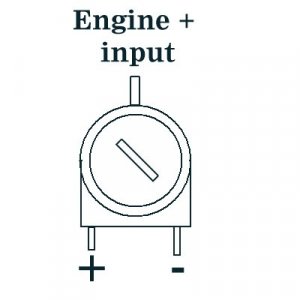

What I would try is to put a trim pot on the + voltage feed to the enging motor. Here is a diagram of how it would be wired in. A 1K pot would probably be a good start. The pot is a small flat round button-like thing with three leads and will look like the second pic. The rectangle in the middle is a slot that can be turned with a small screwdriver.

Attachments

For those of you unfamiliar with electronics, a "pot" is short for potentiometer. It is a variable resistor. A trim pot, as Pitchwife suggests, would be a better solution than trying dozens of different resistors until you find the right one. The resistance on a trim pot can be adjusted by turning the little screw.

That is a good solution, but just be careful since most trimpots are rated at very low power, usually 1/8 to 1/4 watt, That may not be enough. Trying to find room for a bigger pot may be difficult in N scale.Zman said:For those of you unfamiliar with electronics, a "pot" is short for potentiometer. It is a variable resistor. A trim pot, as Pitchwife suggests, would be a better solution than trying dozens of different resistors until you find the right one. The resistance on a trim pot can be adjusted by turning the little screw.

Come to think of it, is your train so long that one real engine can't pull it? You could always use a couple of dummy engines for that prototypical look.

I've thought of using dummys, or at least 1. I'd have to make my runners dummys, as I don't think they are available from LL, or at least not in any quantity.

I like the potentiometer idea, but I don't think there is room in the N scale version to put one. :cry:

No DCC; our club isn't running it and my home layout will be too small to really utilize it as well.

I like the potentiometer idea, but I don't think there is room in the N scale version to put one. :cry:

No DCC; our club isn't running it and my home layout will be too small to really utilize it as well.

ddavidv said:I'm trying to put together a 3 loco set to pull a longer train comprised of Life-Like N scale F7's. In running the pair together last night and having some coupler issues, the two became separated. It is plain that one is much faster at the same throttle setting than the other. Is there any way to correct this? (I'm guessing probably not) Will this cause damage to either loco if they are run connected in this fashion? (I'm guessing yes) Is there any other solution aside from getting a few more chassis and finding a couple that are close?

This is one of the oldest problems in the hobby that can be overcomed..First put the faster unit in the rear and the slower leading.The faster unit will slow down as it bites into the train and thus both units will work together..I use this method for years and am yet to damage a locomotive..That is the trick my Dad taught me many years ago..Try it and see what happens.

ddavidv said:I like the potentiometer idea, but I don't think there is room in the N scale version to put one. :cry:

QUOTE]

You should have plenty of room for a trim pot like I posted. The real thing is actually quite a bit smaller than the picture and flat to boot.

ezdays said:That is a good solution, but just be careful since most trimpots are rated at very low power, usually 1/8 to 1/4 watt, That may not be enough. Trying to find room for a bigger pot may be difficult in N scale.

If the wattage rating is too low, 1/4 watt resistors could be added to the pot legs. I really don't think it would be a problem though. I've used them on many projects and never had any problem with them. At 12v, a 1/4 watt trim pot will handel 3 amps. I would think that that would be enough to pull all but a really heavy train up a steep grade by itself. You want to do this to use it in a consist, so unless you are hauling more than 100 loaded cars, a 1/4 watt trim pot should be no problem.

It's not good to do so. I've done it with HO locomotives. It causes wheel slip which wears out the wheels and will eventually burn up one of the motors. If running DC the best thing to do is run the same brand loco's with the same gearing ratio. I've gone threw a few motor replacements.