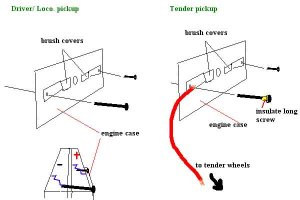

Has anyone ever converted a steam locomotive engine from driver-pickup to tender-pickup? Is it much of a pain in the neck? I think I know how to wire it up , but the problem I face is a long brass bolt that holds on the brush case over the motor, which allows for conduction to that brush.

The reason I want to do this is so I can have a solid metal primary drive axle, and be rid of this wretched Bachmann problem with irreplaceable plastic parts.

The reason I want to do this is so I can have a solid metal primary drive axle, and be rid of this wretched Bachmann problem with irreplaceable plastic parts.