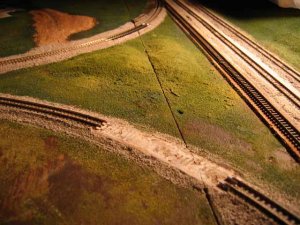

As you might have seen in previous posts of my Wye modules I had just laid the track and roadbed across the separation point of the two modules then took the dremel and cut them causing a natural insulation gap for my auto reverser. Well after The debuts with the wye in with the other modules i noticed it was quite a hassle to stage trains on the tail of the wye then just pull them out onto the main. I had to go quite slow over the area that I had cut and that still sometimes ended up in derailments. So I decided to go back to the drawing board this weekend and cut out the track big enough for a piece of 19" radius snap track with insulated rail joiners on one end of the section. I decided to use 19" radius instead of a straight section because the wye is generally 19" all the way through. Well heres the pics......

Bridging the Wye

- Thread starter b28_82

- Start date

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

If you plan to match tracks over a joint like that without joiners, you need to make the rail ends really secure. I put screw into the base board and solder the rails to them. (actually, I use joiners as well!). You also need some way to line the modules up accurately every time.

Your new solution looks much simpler.

Your new solution looks much simpler.

I made sure they line up every time with dowel rods in one side and holes matching the dowel rods on the other one. (Perhaps I should take pictures of that method.) Then i laid the track but I think this is a learning experience for N scale that even if you use rail spikes and ballast the track prior to cutting, you will still have problems on curves. Didn't you have a "how to" for the screws soldered to the rails?

Not much of a "how to", but it may have been mentioned in my spline roadbed thread. The only trick I had was using Roberston square slot screws, and tinning them before screwing them in. Probably won't work with foam roadbed.