Gary S. said:Are we getting to the point of " six of one, half a dozen of the other" ?

Probably... but that is half the fun...!

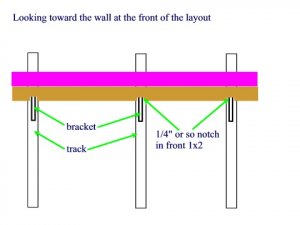

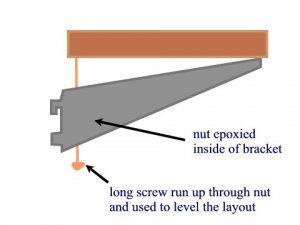

If you are still thinking of proceeding with the "modular" approach, I would definitely make the modifications to the shelf bracket to get everything level. Then you can install the modules "free-floating" as mentioned in previous posts. That way it will be simple to tie the modules to the shelf, rather than trying to build the "correction" into the frame of the module.

Andrew