As promised, I documented my process of laying cork roadbed where turnouts are concerned. I will try to explain to the best of my ability. But, before we begin, here are a couple of tips:

One, when you split the cork apart, you will notice that one side comes out pristine, while the other side has a jagged edge. This is quick and easy to remedy: Just lay that piece along the edge of a 2x4 or other edge and, using a sanding drum on your dremel, just sand it off! Works like a charm and is quick to do.

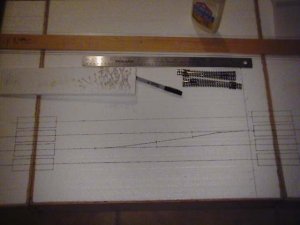

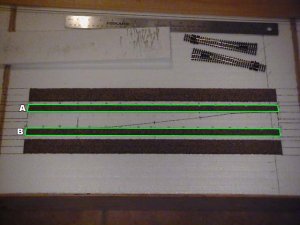

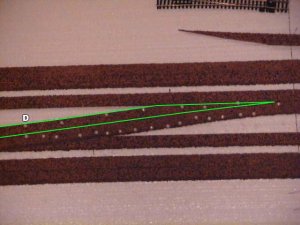

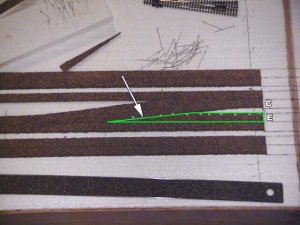

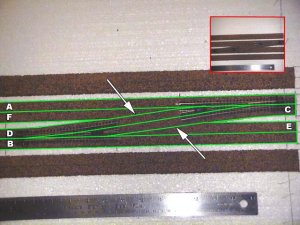

Two, draw the centerline of your tracks on your surface before you begin "corking." This makes life much easier. For my demonstration, I will be laying the roadbed on part of my NTRAK module for the 2004 BBQ. This contains a crossover using Peco #8 turnouts:

One, when you split the cork apart, you will notice that one side comes out pristine, while the other side has a jagged edge. This is quick and easy to remedy: Just lay that piece along the edge of a 2x4 or other edge and, using a sanding drum on your dremel, just sand it off! Works like a charm and is quick to do.

Two, draw the centerline of your tracks on your surface before you begin "corking." This makes life much easier. For my demonstration, I will be laying the roadbed on part of my NTRAK module for the 2004 BBQ. This contains a crossover using Peco #8 turnouts:

![cork-results[1].jpg](/data/attachments/10/10058-7ea2dc74e1c04c3444d6b15e1027f9ae.jpg)