Hi all,

This time it is called to pass through my workshop the Willys Jeep from Modelik.

Historical frame

The history of the Jeep begins the 11 of 1940 July when the Army of the EE.UU summoned 135 car manufacturers to participate in the contest to design a hybrid vehicle of adaptable general intention to recognition missions and control. 49 days were granted to them to present/display the proposals of design and 75 to make the first 70 prototypes.

Only three companies accepted American Bantam Car Company, Ford Motor Company and Willys-Overland Motors and of them, Bantam was the unique one that was able to display a vehicle of test in 49 days and models of production in 75.

Nevertheless due to the precarious economic situation of Bantam, the Government of the EE.UU decided that this one yielded the planes to the other two companies and in November of 1940 these displayed their own prototypes, which turned out to be very similar, reason why 1,500 units were in charge of test to each one.

In July of 1941 it adjudged to Willys the order of 16,000 units of his design, mainly, to the greater power of his motor. Nevertheless in October of 1941 it was evident that single Willys could not satisfy the demand of units of the vehicle, reason why also the production of the model was in charge to Ford.

During the World War II, Willys produced 363,000 units and Ford 280.000. Approximately 51,000 of these vehicles were exported to Russia based on the Lend-Lease program, which was the denomination under which enormous amounts of military equipment were provided to the allies of EE.UU.

Where comes from the Jeep word?

There are different histories about the origin from the Jeep term. One talks about to that Ford used denomination GP for his first models of this vehicle. And in English initials GP they are possible to be read like Jeep. Another history talks about to that the soldiers during the World War I denominated “jeep” to the inexperienced recruits who had still not received formation or to any piece of equipment that had still not passed the burn in. Still another history talks about to its origin in “Eugene the Jeep” a personage who accompanied Popeye and that was able to cross rivers, to raise mountains, etc. The soldiers gave this denomination to the new vehicle by their impressive similar capacities.

References:

Willys MB - Wikipedia, the free encyclopedia

Jeep - Wikipedia, the free encyclopedia

Official Jeep Site - 4x4 SUV, Sport Utility Vehicle

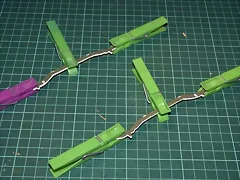

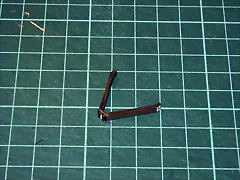

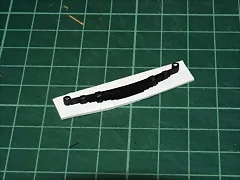

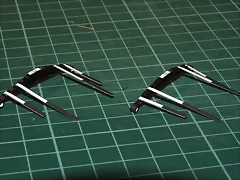

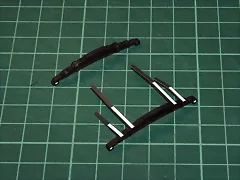

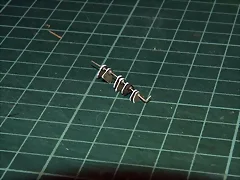

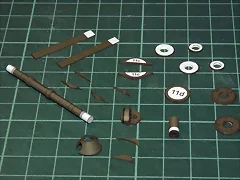

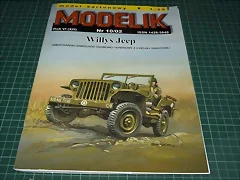

and after this historical review, in Picture 1 I show the model to you. It is notebook 2002 10 from Modelik.

1.

This is all at this moment, more to come soon.

Bye.

This time it is called to pass through my workshop the Willys Jeep from Modelik.

Historical frame

The history of the Jeep begins the 11 of 1940 July when the Army of the EE.UU summoned 135 car manufacturers to participate in the contest to design a hybrid vehicle of adaptable general intention to recognition missions and control. 49 days were granted to them to present/display the proposals of design and 75 to make the first 70 prototypes.

Only three companies accepted American Bantam Car Company, Ford Motor Company and Willys-Overland Motors and of them, Bantam was the unique one that was able to display a vehicle of test in 49 days and models of production in 75.

Nevertheless due to the precarious economic situation of Bantam, the Government of the EE.UU decided that this one yielded the planes to the other two companies and in November of 1940 these displayed their own prototypes, which turned out to be very similar, reason why 1,500 units were in charge of test to each one.

In July of 1941 it adjudged to Willys the order of 16,000 units of his design, mainly, to the greater power of his motor. Nevertheless in October of 1941 it was evident that single Willys could not satisfy the demand of units of the vehicle, reason why also the production of the model was in charge to Ford.

During the World War II, Willys produced 363,000 units and Ford 280.000. Approximately 51,000 of these vehicles were exported to Russia based on the Lend-Lease program, which was the denomination under which enormous amounts of military equipment were provided to the allies of EE.UU.

Where comes from the Jeep word?

There are different histories about the origin from the Jeep term. One talks about to that Ford used denomination GP for his first models of this vehicle. And in English initials GP they are possible to be read like Jeep. Another history talks about to that the soldiers during the World War I denominated “jeep” to the inexperienced recruits who had still not received formation or to any piece of equipment that had still not passed the burn in. Still another history talks about to its origin in “Eugene the Jeep” a personage who accompanied Popeye and that was able to cross rivers, to raise mountains, etc. The soldiers gave this denomination to the new vehicle by their impressive similar capacities.

References:

Willys MB - Wikipedia, the free encyclopedia

Jeep - Wikipedia, the free encyclopedia

Official Jeep Site - 4x4 SUV, Sport Utility Vehicle

and after this historical review, in Picture 1 I show the model to you. It is notebook 2002 10 from Modelik.

1.

This is all at this moment, more to come soon.

Bye.