Why er I mean WYE

- Thread starter shamus

- Start date

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

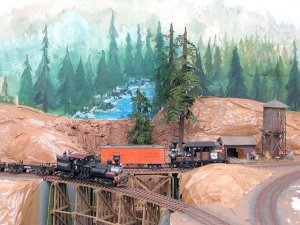

Looking good!

Looking good, Shamus!

Umm.. is that some sort of plastic sheeting you have covered the scenery with?

Looking good, Shamus!

Umm.. is that some sort of plastic sheeting you have covered the scenery with?

Shamus,

I'm guessing, but that 50 ton class B sidewinder #3 looks like a Model Die Casting engine. I have one of those kits, and haven't completed it because I can't get it to run as smooth, and as quiet as I want it to.

I am working on an idea to use "V" belt drive to the engine crankshaft to provide drive through the side gears, and have removed the original worm drive. All that remains of the truck gearboxes is the bolster area. The drivers have been re-installed on pointed axels, and the sideframes modified to accept those axels. The engine coasts very smoothly, and if I can't get a drive mechanism that works, I can still "dummy" the engine with a Bachmann spectrum.

If you think I'm completely mad, patronize me, I'm also reworking an Arbour Models Allegheny kit with new drivers, and full working equalization, and I still have more trees to grow.

Great photos !

Pete

I'm guessing, but that 50 ton class B sidewinder #3 looks like a Model Die Casting engine. I have one of those kits, and haven't completed it because I can't get it to run as smooth, and as quiet as I want it to.

I am working on an idea to use "V" belt drive to the engine crankshaft to provide drive through the side gears, and have removed the original worm drive. All that remains of the truck gearboxes is the bolster area. The drivers have been re-installed on pointed axels, and the sideframes modified to accept those axels. The engine coasts very smoothly, and if I can't get a drive mechanism that works, I can still "dummy" the engine with a Bachmann spectrum.

If you think I'm completely mad, patronize me, I'm also reworking an Arbour Models Allegheny kit with new drivers, and full working equalization, and I still have more trees to grow.

Great photos !

Pete

Hi Shamus

Your layout is awesome and is progressing at an amazing rate. I've been looking through some of the older posts on this forum and your website. All I can say is wow! Thanks for posting the regular updates, its great to see. Your new sawmill in the another post I've seen is just amazing. Looking forward to seeing the Badger-Creek progress.

David

Your layout is awesome and is progressing at an amazing rate. I've been looking through some of the older posts on this forum and your website. All I can say is wow! Thanks for posting the regular updates, its great to see. Your new sawmill in the another post I've seen is just amazing. Looking forward to seeing the Badger-Creek progress.

David

Shamus, I know it was in another thread, but I can't find it. I was wondering how big that access hatch of yours was??? I'm planning on at least one in my final layout, and it's currently 2' x 2'. Is that big enough???

Michael;

Isn't the best way to judge how large an access hatch should be is to take a quick look in the mirror.

I have one hatch that is 24" X 13" and it isn't large enough on the 13" side. I can easily get up through it, but turning around becomes something of a chore.

Bob

Isn't the best way to judge how large an access hatch should be is to take a quick look in the mirror.

I have one hatch that is 24" X 13" and it isn't large enough on the 13" side. I can easily get up through it, but turning around becomes something of a chore.

Bob

I was thinking along the same lines. Maybe cut a hole in a piece of cardboard and see if you're able to get though it. Gotcha's that come to mind are

1) Don't forget you have to get into the hole, not just fit once you're in it (allow for shoulders, etc,

2) Make sure you have enough room to get tools, power cords, whatever, up and onto the surface, and

2) Don't forget to allow for "future expansion" (of you, not the layout!)

1) Don't forget you have to get into the hole, not just fit once you're in it (allow for shoulders, etc,

2) Make sure you have enough room to get tools, power cords, whatever, up and onto the surface, and

2) Don't forget to allow for "future expansion" (of you, not the layout!)

I think maybe your #2 is the most important. If you can't see where you are putting tools, etc. up through the hatch and onto your finished scenery before you go up into it you might wish you made the hatch big enough to drag them up after you are in place. Another idea you just gave me is to build a small shelf into the benchwork to place your tools, etc. on. You can then just reach down to get them rather than have to come up and down through the hatch yourself to fetch what you left on the floor. In my case, with the small hatch, I would probably build a shelf on each side.

In my case, with the small hatch, I would probably build a shelf on each side.

Bob

Bob