Hi All,

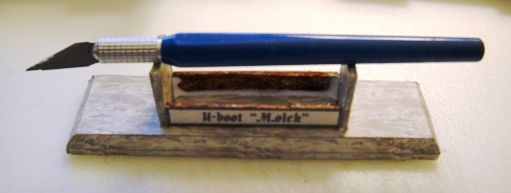

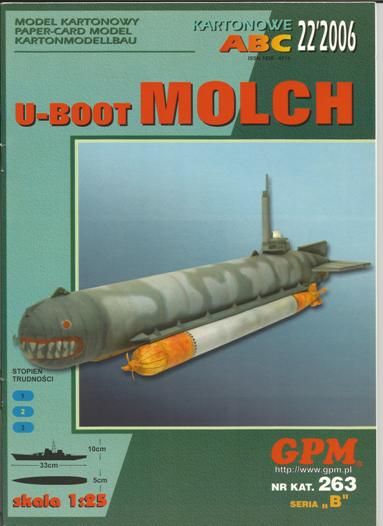

I decided that I just had to start this one even though I have a couple of other irons in the fire. The only mention of one of these that I have been able to locate on the site here is where one of the members mentioned one that he had built and taking it to an IPMS meeting. This is GPM's Kit #263 Series "B". It consists of four pages printed on card and one small 2" X 2" paper sheet of parts, that is probably where the Series "B" designation comes in, the extra parts included which are a series of circle forms to help stiffen the structures internally. There are four pages of pictograph style instructions as part of the booklet. As you can see by the cover artwork, this one was published in 2006, but it is still available and there are even a set of laser cut frames available from GPM for it as well.

The Molch or "Salamander" was Germanys' first sucessful Mini U Boat. It was 11 tons, travelled completely underwater, carried two G7e Torpedos slung along it's bottom sides and went anywhere from 3 to 5 knots on it's missions with about a 50 mile range. It used electric torpedo technology to power it's motor by a bank of chemical batteries. It was a bit difficult to keep trimmed up in operation and had a very low sucess rate sinking roughly 10 to 12 ships and damaging a few more. As other more sucessful designs were developed they were relagated to training roles.

I have found a couple of other build threads to assist me in my build, uh, yeah, I will check out as much helpful information as I can dig up in building these things. I have found a number of reference photos from all over the world from real ones, there seem to be a number of them in museum collections in Europe, to other models, resin, styrene and card in various scales.

I decided that I just had to start this one even though I have a couple of other irons in the fire. The only mention of one of these that I have been able to locate on the site here is where one of the members mentioned one that he had built and taking it to an IPMS meeting. This is GPM's Kit #263 Series "B". It consists of four pages printed on card and one small 2" X 2" paper sheet of parts, that is probably where the Series "B" designation comes in, the extra parts included which are a series of circle forms to help stiffen the structures internally. There are four pages of pictograph style instructions as part of the booklet. As you can see by the cover artwork, this one was published in 2006, but it is still available and there are even a set of laser cut frames available from GPM for it as well.

The Molch or "Salamander" was Germanys' first sucessful Mini U Boat. It was 11 tons, travelled completely underwater, carried two G7e Torpedos slung along it's bottom sides and went anywhere from 3 to 5 knots on it's missions with about a 50 mile range. It used electric torpedo technology to power it's motor by a bank of chemical batteries. It was a bit difficult to keep trimmed up in operation and had a very low sucess rate sinking roughly 10 to 12 ships and damaging a few more. As other more sucessful designs were developed they were relagated to training roles.

I have found a couple of other build threads to assist me in my build, uh, yeah, I will check out as much helpful information as I can dig up in building these things. I have found a number of reference photos from all over the world from real ones, there seem to be a number of them in museum collections in Europe, to other models, resin, styrene and card in various scales.