I have been working on a Walthers turntable and though the parts look good, the mechanics are not very good.

I have taken a piece of 1/2" by 3/16" steel under the desk and drilled it to accept a 1/4" steel rod which I have run through a bronze bushings in a piece of wood under the pit. I have added a ring of c-55 rail to the pit inside of the fake molded in rail and powered the track with wiper pickups on the bridge touching the rail.... so far so good! It turns flat and fairly free...and has some mass wich the original did not.

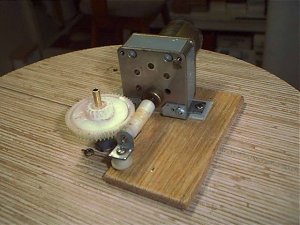

Now I need to motorize the bridge. I am wondering what I should use. I would think something like a 1 or 2 RPM geared DC motor. I need to connect to a 1/4" shaft. Anyone have a source on these? I have tried googling a few places and really am bewindered by the options.

I was also wondering if once I find a motor/gearbox should I connect to the spindle with a flexable (rubber?) connection or something hard?

Any ideas?

I have taken a piece of 1/2" by 3/16" steel under the desk and drilled it to accept a 1/4" steel rod which I have run through a bronze bushings in a piece of wood under the pit. I have added a ring of c-55 rail to the pit inside of the fake molded in rail and powered the track with wiper pickups on the bridge touching the rail.... so far so good! It turns flat and fairly free...and has some mass wich the original did not.

Now I need to motorize the bridge. I am wondering what I should use. I would think something like a 1 or 2 RPM geared DC motor. I need to connect to a 1/4" shaft. Anyone have a source on these? I have tried googling a few places and really am bewindered by the options.

I was also wondering if once I find a motor/gearbox should I connect to the spindle with a flexable (rubber?) connection or something hard?

Any ideas?