Good day folks.

A couple months back, I posted my initial impressions of the P2K loco, along with some information about my initial efforts to install a Soundtraxx Tsunami decoder and speaker. I took a bunch of pictures with the intent of posting them later, but only now am getting around to it!

The initial post is here: http://www.the-gauge.com/showthread.php?t=21472&highlight=0-6-0

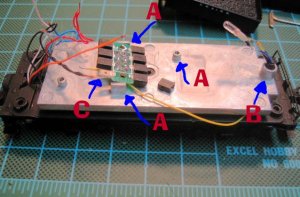

My 0-6-0 started as a DC model. The guts of the tender included a small circuit board, along with an NMRA-type "DCC ready" plug. After getting the Tsunami, it became apparent that there was no way I was going to be able to fit the decoder and speaker and still use the factory provided plug. The first photo shows the unmodified chassis. All parts of the casting that rose above the floor were eventually removed (a couple are marked A in the photo - excepting the light mounting tube. I did this for two reasons - to give myself as much flexibility as possible in the location of the decoder and to give the decoder alot of surface contact with the chassis weight so it could be used as a heat sink.

I also ended up modifying the light mount to accomdate an LED - it had to both be shortend and "opened" on one side to give me access to the cathode and annode. More in next post.

A couple months back, I posted my initial impressions of the P2K loco, along with some information about my initial efforts to install a Soundtraxx Tsunami decoder and speaker. I took a bunch of pictures with the intent of posting them later, but only now am getting around to it!

The initial post is here: http://www.the-gauge.com/showthread.php?t=21472&highlight=0-6-0

My 0-6-0 started as a DC model. The guts of the tender included a small circuit board, along with an NMRA-type "DCC ready" plug. After getting the Tsunami, it became apparent that there was no way I was going to be able to fit the decoder and speaker and still use the factory provided plug. The first photo shows the unmodified chassis. All parts of the casting that rose above the floor were eventually removed (a couple are marked A in the photo - excepting the light mounting tube. I did this for two reasons - to give myself as much flexibility as possible in the location of the decoder and to give the decoder alot of surface contact with the chassis weight so it could be used as a heat sink.

I also ended up modifying the light mount to accomdate an LED - it had to both be shortend and "opened" on one side to give me access to the cathode and annode. More in next post.