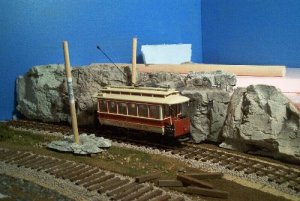

Management at the Megill River Lumber Co. are looking at a great deal on a little electric tram for running their workers to and from the logging jobsite. We're talking about a short stretch of rickety track, not too well-maintained, and as the loggers are getting a free ride, they wouldn't grumble too much about getting out and helping re-attach the pole to the guy wire. I'm thinking poles canted at the not-quite square, not-quite uniform height...but work in a pinch.

What diameter trolley poles should they use? Could they even string the wire up through existing trees? Wouldn't that be cool?

What diameter trolley poles should they use? Could they even string the wire up through existing trees? Wouldn't that be cool?