I used HO scale cork for my mainlines and wish to use something smaller for branchlines as the cork looks too big, any suggestions, and how do I go about the transition so I don't have a low spot for trains to uncouple.

transition from mainline to branch

- Thread starter basementdweller

- Start date

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

F

Fred_M

You can use N scale cork or as Fred suggests the thinner sheet cork or as I did in my yard nothing, which drops it down considerably lower than the mains. It's your choice!

What Fred suggested is fine for a yard, if you want a suggestion of roadbed height but want to make the secondary trackage lower than the main, you can still use the cork he suggested, cut to the appropriate width strips. Shoulders can be shaved. The HO cork can be shaved down over a foot or so distance to meet the height of the sheet cork. I've also used N scale cork, but when you align the two halves so their shoulders are even with the HO cork, you have a strip down the center with no cork. I just filled that in with spackle.

Shaving the cork, for me, has been a PITA. Perhaps others have suggestions on how to do it. Instead, I've often built up a "ramp" on top of the lower cork. I take a piece of plywood (1/2" or more) some wax paper and a can of expandable foam. If there is a curve I cut the plywood to match the curve. The plywood will be screwed down at each end of the ramp, and its bottom side covered with the wax paper. Do not attach the wax paper to the wood. When the wood fits properly, apply the foam, put the wood on top and screw it down. When you remove the wood the wax paper will stay on the foam, you can trim the edges and leave it. Use knife,rasps or surform tool to get rid of the excess foam which came out the sides. I did this first on a s curve dropping 1/4 from a main to a freight house siding over a distance of 2 feet, it was easier than anything else I could think of at the time.

Shaving the cork, for me, has been a PITA. Perhaps others have suggestions on how to do it. Instead, I've often built up a "ramp" on top of the lower cork. I take a piece of plywood (1/2" or more) some wax paper and a can of expandable foam. If there is a curve I cut the plywood to match the curve. The plywood will be screwed down at each end of the ramp, and its bottom side covered with the wax paper. Do not attach the wax paper to the wood. When the wood fits properly, apply the foam, put the wood on top and screw it down. When you remove the wood the wax paper will stay on the foam, you can trim the edges and leave it. Use knife,rasps or surform tool to get rid of the excess foam which came out the sides. I did this first on a s curve dropping 1/4 from a main to a freight house siding over a distance of 2 feet, it was easier than anything else I could think of at the time.

F

Fred_M

Ramps, build them from lamanated cerial box. Make each strip a bit shorter and cover them when done with the thinner cork. The box thickness makes a smoother transition when covered with cork than you may think. Fred

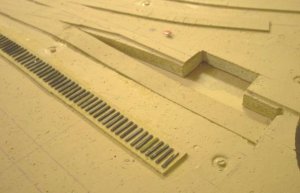

I bought cork tiles (1 ft square, thickness about 1/8") in a do-it-yourself center. Then I cut strips wide enough for the tracks (here it's narrow gauge) and glued them to the subroadbed. Finally I painted the whole thing with earth colored latex paint before adding the tracks.

As Fred suggested, in a yard I would use the full size tiles because yard tracks nearly always are level with the ground.

The pic shows the future ashpit of my loco terminal. On the siding in the foreground I already added the ties for my handlaid track.

So far I'm happy with this sort of roadbed.

Ron

As Fred suggested, in a yard I would use the full size tiles because yard tracks nearly always are level with the ground.

The pic shows the future ashpit of my loco terminal. On the siding in the foreground I already added the ties for my handlaid track.

So far I'm happy with this sort of roadbed.

Ron

Attachments

Let me run this by you, today I noticed on a local branch line that the rail ties are almost sunken into the ground and what little ballast there is spreads out quite a bit, no defined shoulder of any kind. Couldn't I recreate this by not using any cork at all and just place the flex track directly on the foam base and spread some ballast around the ties? Am I missing something?

Thanks for all the ideas.

Thanks for all the ideas.

Yes you can!!! Alot of branches aren't well maintained and there is no defined shoulder, besides speeds on these are usually slow anyway, they don't need to be well maintained.

If you're putting it on foam you don't need any sound deadening qualities of cork.

Go for it.

If you're putting it on foam you don't need any sound deadening qualities of cork.

Go for it.

dats whad I do Check back for better pix soon. I've used door shims for for the ramp in the past as well as other idears mentioned.

When I have to ramp flextrack down, I just lay one end on the high part, then attach the other end to the low part. I let the track form a natural vertical curve, then fill the void with ballast (sand or dirt would work to conserve ballast) and soak it when gluing the ballast. Looks good, and you don't have to worry about sharp vertical curves.

A poorly maintain branch line lacks the profiles of the main lines has was stated.If you are using foam or homasote way bother with any road bed? After all you want that low maintenance look..Now,I use then cardboard to sloop my track from the main line roadbed(the very few times I have use it) to my industrial siding and in some cases the yard area..

http://www.shortlinesusa.com/A_r501_copy.jpg

http://www.shortlinesusa.com/valdosta184.jpg

http://www.dtirr.com/upeB2B3.jpg

http://www.shortlinesusa.com/A_r501_copy.jpg

http://www.shortlinesusa.com/valdosta184.jpg

http://www.dtirr.com/upeB2B3.jpg

F

Fred_M

Because most yards are not in a hole guys. They raise the ground in the yard to match main track heigth. Even in a hump yard they raised the hump higher, not the mains nor lower the yard. They attempt to keep the tracks level as possibe, lots of through traffic go through yards without stopping. That's why I build up with cork rather than lower the mains. Fred