Gary S. said:P.S. I really like your tagline!

Hey thanks. Too bad I can't take credit for it eh?

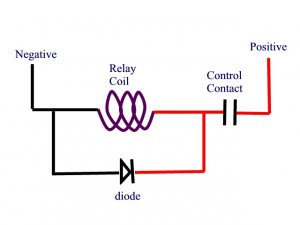

About the power supply. I'm an idiot when it comes to electrical. When you start talking about capacitors and amperage I zone out and think to myself, "oooo...look at the pretty lights!" A picture is worth a thousands words in my case my friend. I need to see how the finished project looks from the plug in the wall all the way to the device it powers or operates. Only then do I start to get "it".

Thank you so far. This has been a great source for something I want to include on my layout. If there is a way to do it, I'd love to give it a shot.