a while back in chat room we were talking about a stub switch as they say a picture is worth a 1000 words here is a three way stub on the SP narrow gauge.i think and correct me if wrong but expression bending the rails might have come from this type of switch

stub switch or turnout

- Thread starter jim currie

- Start date

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

cidchase

Active Member

Oh, yeah, that's what I'm talkin' about!!!

If I ever get to my Narrow gauge section, I'm going to

try hand-laying the stub switches. Actually, that 3-way

might fit right into my scheme!!

Thanx, Jim

If I ever get to my Narrow gauge section, I'm going to

try hand-laying the stub switches. Actually, that 3-way

might fit right into my scheme!!

Thanx, Jim

Nice photo, Jim.

I'm determined to use stubs on my new layout.

All indications are that they will actually be easier to lay than point turnouts. They're much simpler. I've even experimented with modifying off-the-shelf Atlas turnouts, which doesn't look at all bad (Tho' I'd really rather hand lay them).

But for the life of me I've not been able to come up with a way to actuate them and insure they line up each time. With point turnouts, all you need do is slam the points against the rails. But with stubs, the movable rails don't bang up against anything, so the alignment promises to be much stickier. Anyone have any advice?

And by the way, it wasn't just the narrow gauge lines that used them; essentially all turnouts were stubs before some time in the 1880's or so.

BillS

I'm determined to use stubs on my new layout.

All indications are that they will actually be easier to lay than point turnouts. They're much simpler. I've even experimented with modifying off-the-shelf Atlas turnouts, which doesn't look at all bad (Tho' I'd really rather hand lay them).

But for the life of me I've not been able to come up with a way to actuate them and insure they line up each time. With point turnouts, all you need do is slam the points against the rails. But with stubs, the movable rails don't bang up against anything, so the alignment promises to be much stickier. Anyone have any advice?

And by the way, it wasn't just the narrow gauge lines that used them; essentially all turnouts were stubs before some time in the 1880's or so.

BillS

I don't know how to do a 3-way, but the for other ones we used to put some heavy spikes along the outside of the rails. May not be prototypical, but it worked.

Thought: You might rig it to a 3 way slide switch under the table. You'll need some sort of contacts for the frogs and stock rails.

Thought: You might rig it to a 3 way slide switch under the table. You'll need some sort of contacts for the frogs and stock rails.

I'll definitely be keeping an eye on this thread, hoping for advice from somebody who has done them. I plan to be laying track in the coming year on some lumber company trackage, Code 70, standard gauge in HO. I hope to use stubs there along with harp switchstands, but have never laid track this way before. My handlaid to date has all been Code 83 with either switch machines or Caboose Industries switch stands.

Question: Should a switch motor with an adjustable throw, like the Tortoise, be the thing to use on tracks I cannot reach easily?

--Stu--

Question: Should a switch motor with an adjustable throw, like the Tortoise, be the thing to use on tracks I cannot reach easily?

--Stu--

I remember reading an article in MR or RMC about setting up under table switch motors to line up a 3 way stub switch.

I used hand layed stub switches on an HOn30 line on one of my old layouts. They worked rather well.

I used hand layed stub switches on an HOn30 line on one of my old layouts. They worked rather well.

Hey, thanks Ray. I did a search of the all-time model RR periodical index on Kalmbach's website. The most likely candidates are Oct. 65 MR and MR of Jan. 86.

The Jan. 78 NMRA Bulletin carried an article specifically about 3-way stub switches. as did the Apr. 2001 MR.

The index itself can be found at http://index.mrmag.com/

--Stu--

The Jan. 78 NMRA Bulletin carried an article specifically about 3-way stub switches. as did the Apr. 2001 MR.

The index itself can be found at http://index.mrmag.com/

--Stu--

I've never tried laying a stub switch, but one thing that comes to mind for throwing them, especially the three-way, is a manual screw-drive. Attach a nut to a rod, attached to the "points" or whatever you call them on a stub turnout. Thread a piece of threaded rod thru it and anchor it so that when you turn it you move the points. Have a crank of some sort on the other end, and visually line the points up. If you use a fine threaded rod you should be able to line everything up accurately. Maybe have some sort of screw lock on the threaded rod so it'll stay in place once set.

Jim - I don't know if it is specifcally stub switches where that expression comes from, as prototype point-type switches rely on flex in the point rails as well. There is no hinge or pivot as seen on the model turnout.

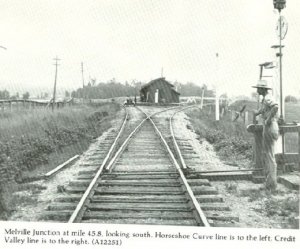

Cid - you do not need to wait to get a narrow gauge line to have a stub switch. Check out this one from the old Credit Valley Railway - thanks to will_annand - the pic below is from his web site.

BillS - there is indeed an article (or maybe more judging by the response). I have at least one of those - let me look it up, and if you want a copy, just PM me your address. The method - if I remember correctly - was to put stops on the outside as David suggested, and then use a retractable stop for the middle position.

MHD - the threaded rod/screw idea sounds like it could really work well.

Andrew

Cid - you do not need to wait to get a narrow gauge line to have a stub switch. Check out this one from the old Credit Valley Railway - thanks to will_annand - the pic below is from his web site.

BillS - there is indeed an article (or maybe more judging by the response). I have at least one of those - let me look it up, and if you want a copy, just PM me your address. The method - if I remember correctly - was to put stops on the outside as David suggested, and then use a retractable stop for the middle position.

MHD - the threaded rod/screw idea sounds like it could really work well.

Andrew

Attachments

did one three way stub switch some time back that used springs to keep in straight position and used pull cords to change to right or left there was a article years ago about this method of switch control

Originally posted by Bill Stone

Nice photo, Jim.

I'm determined to use stubs on my new layout.

All indications are that they will actually be easier to lay than point turnouts. They're much simpler. I've even experimented with modifying off-the-shelf Atlas turnouts, which doesn't look at all bad (Tho' I'd really rather hand lay them).

But for the life of me I've not been able to come up with a way to actuate them and insure they line up each time. With point turnouts, all you need do is slam the points against the rails. But with stubs, the movable rails don't bang up against anything, so the alignment promises to be much stickier. Anyone have any advice?

And by the way, it wasn't just the narrow gauge lines that used them; essentially all turnouts were stubs before some time in the 1880's or so.

Bill, The only one's I seen used the old choke cable method to throw them (from a distance) and you had to sort of "eyeball" them into alignment.

BillS

Stub turnouts sure looks interesting.

For a 2 way stub turnout I would probably use a small nail on each 'outer' position as stops, but for 3 way turnouts I guess you would have to eyeball the center position.

For a 2 way stub turnout I would probably use a small nail on each 'outer' position as stops, but for 3 way turnouts I guess you would have to eyeball the center position.

I love stub switches, they were used in heavy snow country because they didn't freeze up and you didn't have to shovel out snow from between the points. MR did an article on a tie plant that ran three different gauges; 18", 30" and standard. At one point on the plant, there was a three way switch that all three gauges used, that combined point and stub throws. One of their staff took up the challenge and wrote a sub article on the experience.

I really like the screw approach to stub turnout control. One of those ideas that makes you say “why didn’t I think of that.” It’s a derivation of the “choke cable” approach, but sounds like it would hold the rails in place much more reliably, and likely would make it easier to perfectly align the rails in the first place. Of course it means you’d have to eyeball the turnout every time for alignment, but that could be an advantage as I suspect the nails (or whatever) one might use to stop the rails would be miserable to get perfectly located, and might just be subject to moving around over time.

The moveable rails must, of course, not be attached to the ties for some distance. On the prototype the typical approach was to install a number of rods between the rails to keep everything in gauge, and there apparently were usually metal plates on the tie tops for the rails to slide on. I don’t think there was anything to keep the rails down against the ties except for gravity and the weight of stuff rolling over them. I cannot think of any practical model version of these rods. Plastic (anywhere near scale) wouldn’t be stiff enough and metal wire would work only if we didn’t have to keep the rails electrically isolated. I am concerned with keeping the movable (model) rails aligned vertically as well as horizontally, and see that as a potential problem. Model point turnouts have the advantage over stub turnouts, of the tie rod sliding between the rails and the roadbed which keeps the points vertically positioned and level with each other.

I remember one approach in a model magazine many years ago, where flex track was used and the ties were left attached to the rails --- allowed to move with the rails. At first I thought that a great solution, and was what I used in my experiment with modifying Atlas turnouts. Worked great, and although it of course wasn’t prototypical, looked pretty good too. That is until I began to wonder how I would ballast the roadbed in that area. Not only would the ties have to stay loose, the ballast could not get in the way of the ties moving. That would be such a hassle, it caused me to discard the whole idea.

Now I’m thinking that the solution might be to use a wide tie rod (or whatever you want to call the thing that holds the end of the moveable rails in gauge AND moves them.) Wide enough that it slides under the ends of the fixed rails as it moves the moveable rails. It would take some thinking to keep it from looking clunky. Perhaps it could be made to look like two ties with some ballast in between, but in fact the whole thing would move. I know I’m not explaining this well, but my scanner is down so I cannot show you a sketch of what I mean.

BillS

The moveable rails must, of course, not be attached to the ties for some distance. On the prototype the typical approach was to install a number of rods between the rails to keep everything in gauge, and there apparently were usually metal plates on the tie tops for the rails to slide on. I don’t think there was anything to keep the rails down against the ties except for gravity and the weight of stuff rolling over them. I cannot think of any practical model version of these rods. Plastic (anywhere near scale) wouldn’t be stiff enough and metal wire would work only if we didn’t have to keep the rails electrically isolated. I am concerned with keeping the movable (model) rails aligned vertically as well as horizontally, and see that as a potential problem. Model point turnouts have the advantage over stub turnouts, of the tie rod sliding between the rails and the roadbed which keeps the points vertically positioned and level with each other.

I remember one approach in a model magazine many years ago, where flex track was used and the ties were left attached to the rails --- allowed to move with the rails. At first I thought that a great solution, and was what I used in my experiment with modifying Atlas turnouts. Worked great, and although it of course wasn’t prototypical, looked pretty good too. That is until I began to wonder how I would ballast the roadbed in that area. Not only would the ties have to stay loose, the ballast could not get in the way of the ties moving. That would be such a hassle, it caused me to discard the whole idea.

Now I’m thinking that the solution might be to use a wide tie rod (or whatever you want to call the thing that holds the end of the moveable rails in gauge AND moves them.) Wide enough that it slides under the ends of the fixed rails as it moves the moveable rails. It would take some thinking to keep it from looking clunky. Perhaps it could be made to look like two ties with some ballast in between, but in fact the whole thing would move. I know I’m not explaining this well, but my scanner is down so I cannot show you a sketch of what I mean.

BillS

Bill, Don't know if I can explain this clearly. I've been toying with ideas to eliminate the pc board throwbar I use on standard turnouts, so I can use a scale size throwbar. This thought has occured to me but I haven't tried it yet (no turnouts to build just now). Drill clearance holes in bottom of points (in your case, rails) Solder in brass wire, just long enough to clear bottom of your roadbed. They would need to pass through slots as long as the throw. Drill same size holes in a piece of pcb strip, slide it over wires from beneath and solder in place. Attach throw mech to the strip. This now allows you to use scale size plastic rods to maintain gauge. What do you think?

Gary

Gary

Gary,

You explained it just fine. I’ve had similar thoughts in the past, but my versions always got too complicated under the roadbed. I never thought of the pcb strip on the under side, and to my mind that brings the idea right back toward the realm of practicality. The approach has a whole lot going for it (for both stub and point turnouts) as it essentially gets rid of all --- or nearly all --- of the non-prototype junk that shows. And it has other pluses too. For one thing, by sandwiching the roadbed and ties between the rails on the top and the pcb on the bottom, the rails are held in the proper vertical position.

One concern that can only be answered by building one of these things, is whether the wires would be stiff enough to not bend when you asked them to move the rails. Or the wires might pivot in the pcb hole and break the solder joints. The wires cannot be very large diameter, particularly if one is using code 70 rail. I do have a possible solution to that, but words fail me (as has my scanner) so I’ll try it on the work bench and try to explain it with photos --- but I won’t get around to that for a while as I’m up to my eyebrows just now.

Another thought: It might improve the whole thing if one fixed a nylon “plate” to the underside of the roadbed, to act as a bearing for the pcb strip to slide on.

BillS

You explained it just fine. I’ve had similar thoughts in the past, but my versions always got too complicated under the roadbed. I never thought of the pcb strip on the under side, and to my mind that brings the idea right back toward the realm of practicality. The approach has a whole lot going for it (for both stub and point turnouts) as it essentially gets rid of all --- or nearly all --- of the non-prototype junk that shows. And it has other pluses too. For one thing, by sandwiching the roadbed and ties between the rails on the top and the pcb on the bottom, the rails are held in the proper vertical position.

One concern that can only be answered by building one of these things, is whether the wires would be stiff enough to not bend when you asked them to move the rails. Or the wires might pivot in the pcb hole and break the solder joints. The wires cannot be very large diameter, particularly if one is using code 70 rail. I do have a possible solution to that, but words fail me (as has my scanner) so I’ll try it on the work bench and try to explain it with photos --- but I won’t get around to that for a while as I’m up to my eyebrows just now.

Another thought: It might improve the whole thing if one fixed a nylon “plate” to the underside of the roadbed, to act as a bearing for the pcb strip to slide on.

BillS

Bill, I have the same concern, I think the solder joint in the rail would be fine as it is in a drilled hole (original thought was a butt joint, don't think that would last) Although a larger diameter wire could be used with a butt joint. Not sure what type wire other than brass can be soldered and be more rigid. The pcb material may be replaced with brass bar if it could be insulated in half, like loco wheelsets. A tight fit in plastic sleeving? I'd surely prefer the additional solder surface. And yes, some smooth surface to act as a bearing for the throwbar to slide on would be desireable. Unfortunately, I won't be attempting it anytime soon either. Got other projects to finish, and spring is here, time to get outside!

Gary

Gary