After fussing with this Bachmann 0-6-0 for quite some time and hearing others getting frustrated with theirs, I decided to figure out a way to get this loco back into service.

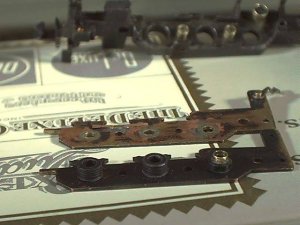

These Bachmanns with their split axle design are known for the axle gears cracking which lets the drivers get out of quarter and jam or the wheels just fall off.

I found that the older Bachmann diesels have a metal gear with the same pitch and number of teeth.

I knew this wasn't going to be an easy fix but I had to see if it would work.

The Diesel gears had to be narrowed and pressed off center on the axles.

Bushings were fabricated and fit into the frame rails.

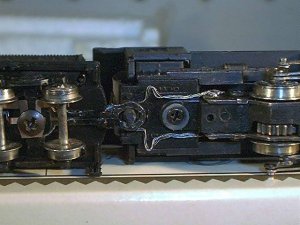

The bushings on one side were soldered to the frame rail. (note the addition of extra pickup wipers soldered to the frame rails also)

The bushings on the other frame rail are plastic with brass sleeves to allow the frame rails to be electrically isolated from each other.

These Bachmanns with their split axle design are known for the axle gears cracking which lets the drivers get out of quarter and jam or the wheels just fall off.

I found that the older Bachmann diesels have a metal gear with the same pitch and number of teeth.

I knew this wasn't going to be an easy fix but I had to see if it would work.

The Diesel gears had to be narrowed and pressed off center on the axles.

Bushings were fabricated and fit into the frame rails.

The bushings on one side were soldered to the frame rail. (note the addition of extra pickup wipers soldered to the frame rails also)

The bushings on the other frame rail are plastic with brass sleeves to allow the frame rails to be electrically isolated from each other.