These are my thoughts on train operation: (I am an operational newbie!)

Possibility 1: Through freights - Stage trains on upper staging and lower staging tracks. One train leaves upper, one train leaves lower. Run both trains to opposite ends, using passing sidings, and go into the staging track left vacant by the other train at the end of the run. Possibly even have more trains leave staging with maybe 3 or 4 trains on layout at once.

Possibility 2: Same as above, except set out and pick up cars at various industries on way to the other staging area. Again, trains could be doing this in both directions.

Possibility 3: Local freight switches industries on the layout, delivering cars from one industry to another industry at different industry areas

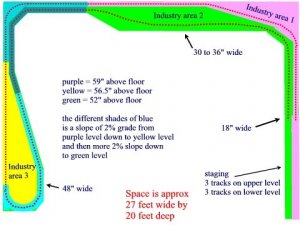

Possibility 4: Question: Would the industry area #2 be big enough to warrant a switcher moving cars to the various industries, cars dropped off by trains coming from the staging areas or other industry areas?

5. Anyone see any other possibilities?

Industries I have thought about:

Industry A: Tank farm, small refinery (ships chemicals out in tank cars to Industry B and off the layout (staging))

Industry B. Plastic pellet manufacturer (recieves chemicals from tank cars and produces plastic pellets, ships pellets out in covered hoppers to Industry C and off the layout (staging))

Industry C: Plastic molding company (receives plastic pellets in hoppers and makes plastic products, molding, ships them out in box cars to staging)

Industry D: Machine shop, metal works, (builds and repairs machinery to be shipped on flat cars and gondolas to off the layout, would occasionally build equipment for industries above and ship them by rail)

Industry E: Packing house, cannery (receive goods in box cars from off the layout and ships packaged items in box cars

That's all I've got for now, any suggestions on this aspect of the layout?