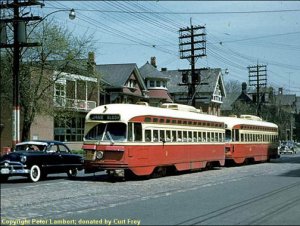

My problem is that Toronto streetcars (that's what we call them here) did not have catenary, or pantographs - 2 things which make the whole issue of live overhead a lot easier. As Will says, our wires are strung from the utility poles, and those same poles carry phone wires and streetlamps.

Until I can get, or make, tapered wood utility poles (with streetlights) for my wire supports, I prefer to run off track power alone. I'm more interested in a prototypical appearance than I am in prototypical wiring, and so far no one makes anything close to what I need. A massive scratchbuild undertaking that I am reluctant to do when I have so many other things to build.

Actually, the lack of catenary makes things SIMPLER--simple trolley wire is much easier to construct than catenary style--and the trolley poles described above would be just fine for your sort of project, because in Sacramento, trolley wire was also strung from utility poles on either side of the street! Rather than constructing an arm, put one pole on either side of the street and run either nickel-silver trolley wire or other 24-28 gauge wire from one "notch" (just above trolley shoe height, remember) to the other, with a couple Indian seed beads to represent insulators.

Span poles (as this setup was called), rather than the single-arm style, are pretty common in cities.

A little brainstorming on the subject--I suppose you could still use piano wire, and just make it a couple inches longer so there would be space for a couple of cross-arms. I did this for my sample length of "trolley wire" layout--I used a Rix utility-pole kit, which includes separate crossarms intended to be glued to their poles, and just glued them to my piano-wire poles instead.

Wiring the streetlamps seems like it would be an interesting project--I suppose you could substitute 1/8" brass tubing for the trolley poles with streetlamps and run a GOW bulb up the middle and out through a hole poked in the tubing for the streetlamp itself--or you could just glue a non-functional streetlamp appliance to the pole. Or you could run the wiring up the side of a piece of solid tubing/wire and paint the whole thing black.

In any case, it would be fairly easy to later add crossarms and streetlamps to a trolley/utility pole that had been cut to the correct height later on.

But hey, I'm not here to tell you how you should construct your layout...and maybe before telling someone else they should put in THEIR trolley poles, I should put in MINE... (hanging head in shame)