In this thread I will demonstrate how I fabricated pantographs for a Pennline GG1.

The materials needed are:

.020" steel or brass wire

.010" brass sheet

1/2" length of 3/32" brass tubing

2 small springs

Materials for the jigs are:

a block of wood

straight pins

two 1/16" dia. roll pins (or 1/16" dia. rod)

1 popsicle stick

Tools needed:

needlenose pliers

fingernail clippers

soldering iron

solder

flux

small alligator clips

spring type clothes-pin

small file

ruler

pencil

scissors (to cut brass sheet)

tubing cutter (or razer saw)

1/16", 3/32", 1/8" drill bits and hand drill

small hammer

magnifier glass

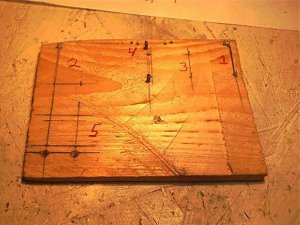

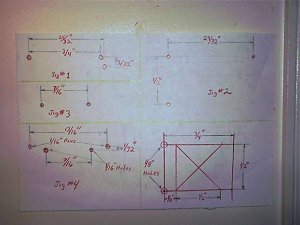

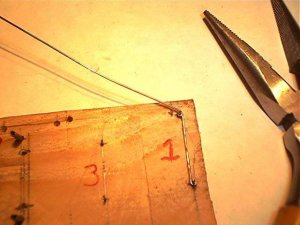

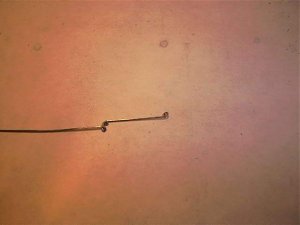

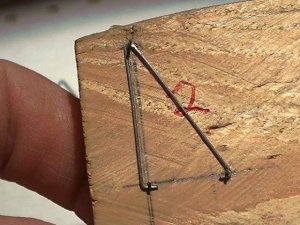

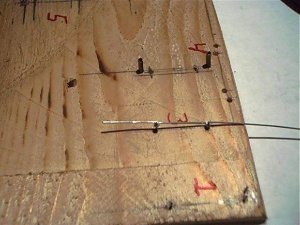

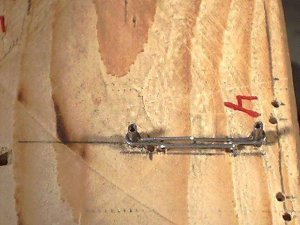

This is a photo of the jigs

The materials needed are:

.020" steel or brass wire

.010" brass sheet

1/2" length of 3/32" brass tubing

2 small springs

Materials for the jigs are:

a block of wood

straight pins

two 1/16" dia. roll pins (or 1/16" dia. rod)

1 popsicle stick

Tools needed:

needlenose pliers

fingernail clippers

soldering iron

solder

flux

small alligator clips

spring type clothes-pin

small file

ruler

pencil

scissors (to cut brass sheet)

tubing cutter (or razer saw)

1/16", 3/32", 1/8" drill bits and hand drill

small hammer

magnifier glass

This is a photo of the jigs