Hi Gang!

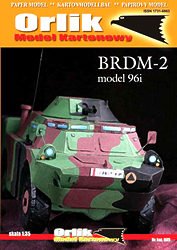

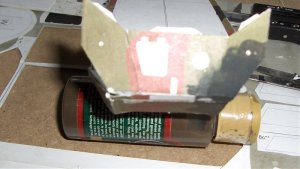

I am in the process of building the ORLIK BRDM-2 mod 96i wheeled recce vehicle as published in 1:35 scale. The ORLIK catalogue number is 005.

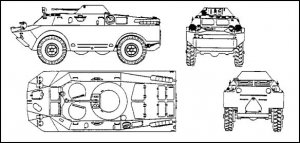

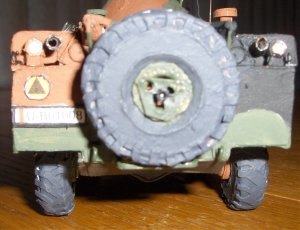

The vehicle as printed represents the Polish/Czech 96i variant of the Soviet BRDM 2 in Polish Army (WkP) service. Unlike the Soviet BRDM2, the 96i does not have "cross country belly wheels". Instead, there are large troop doors in the sides of the hull.

*20 Jan 08: I originally did not plan to paint this model. However, I also did not seal the model sheets before I started assembly, which I normally do.... . I got a rude shock when I sprayed my usual fixative coat after the hull was assembled. It dried completely white!! The can of fixative froze in my shop during a power failure. So, most of the model has, in fact, been painted.....

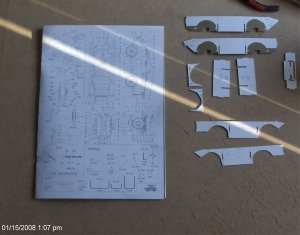

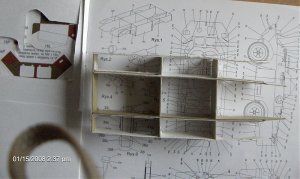

Do not figure upon slapping this model together in an evening. Consider this (at least) as a good 1:35 finescale plastic model and plan to work accordingly.

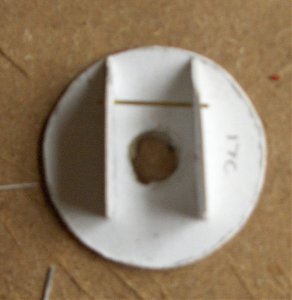

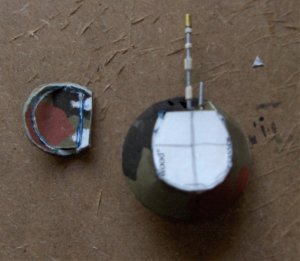

There are lots and lots of often-absurdly tiny parts to deal with here.

I previously did an overview of this kit. http://forum.zealot.com/t140061/

As I go along, I'll try to provide a set of comprehensive instructions and my building tips as no English instruction for this kit is available.

By the way: the cover illustration on the booklet appears to be of a a painted model. The camouflage pattern on the printed model appears to be standard NATO Pattern Woodland Camo, so the appropriate FS colours of whatever paints you use should suffice. (Light Olive Green, Red-Brown, Black)

Now, let us pray!

Jim

I am in the process of building the ORLIK BRDM-2 mod 96i wheeled recce vehicle as published in 1:35 scale. The ORLIK catalogue number is 005.

The vehicle as printed represents the Polish/Czech 96i variant of the Soviet BRDM 2 in Polish Army (WkP) service. Unlike the Soviet BRDM2, the 96i does not have "cross country belly wheels". Instead, there are large troop doors in the sides of the hull.

*20 Jan 08: I originally did not plan to paint this model. However, I also did not seal the model sheets before I started assembly, which I normally do.... . I got a rude shock when I sprayed my usual fixative coat after the hull was assembled. It dried completely white!! The can of fixative froze in my shop during a power failure. So, most of the model has, in fact, been painted.....

Do not figure upon slapping this model together in an evening. Consider this (at least) as a good 1:35 finescale plastic model and plan to work accordingly.

There are lots and lots of often-absurdly tiny parts to deal with here.

I previously did an overview of this kit. http://forum.zealot.com/t140061/

As I go along, I'll try to provide a set of comprehensive instructions and my building tips as no English instruction for this kit is available.

By the way: the cover illustration on the booklet appears to be of a a painted model. The camouflage pattern on the printed model appears to be standard NATO Pattern Woodland Camo, so the appropriate FS colours of whatever paints you use should suffice. (Light Olive Green, Red-Brown, Black)

Now, let us pray!

Jim