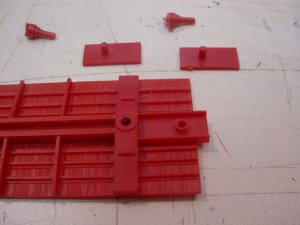

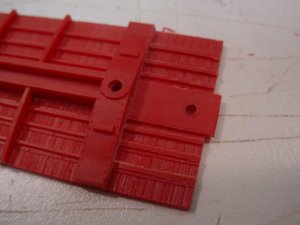

I've decided I like the Accurail kits quite a bit, no, they aren't nearly as detailed as some of the high dollar offerings like Kadees, but on the other hand, they are rugged and will stand up to repeated handling without breaking off grab irons and ladders. Plus the price is right, I often find them at the LHS on sale for 7 or 8 bucks each, and recently found some on sale for $5 each !

!

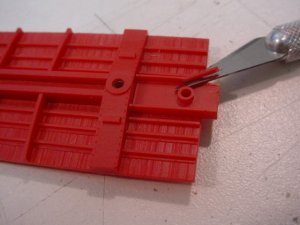

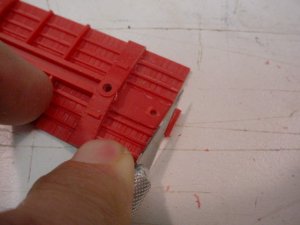

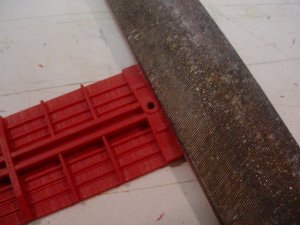

Now, there are a few things I don't like about them, in particular the friction fit draft box lid, the friction pin used to hold the trucks on, the couplers, and the plastic wheels. I'm going to do a tutorial here, aimed primarily at beginners because you expert modelers probably have better ways to do this than I do, plus, I am pretty much a beginner myself. I hope I can give some good info concerning the tools, techniques, and materials used for modifying freight cars to others who are just entering the hobby. And, much of this tutorial can be applied to any of the lower end freight cars such as Life-Like, Athearn, and Roundhouse kits.

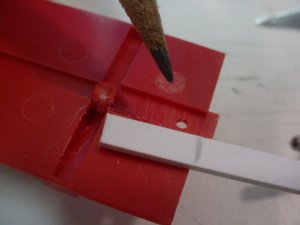

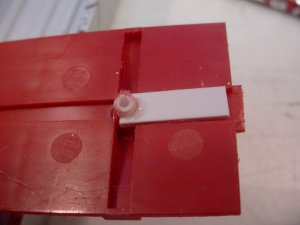

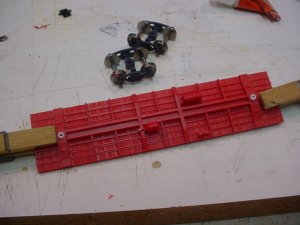

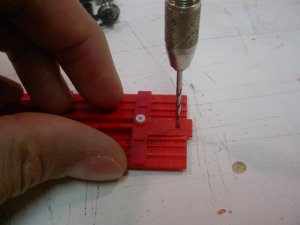

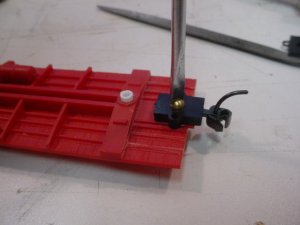

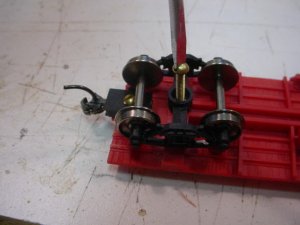

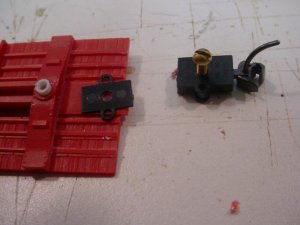

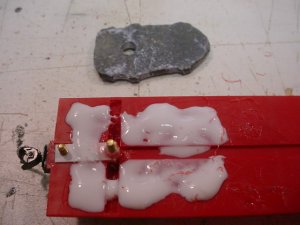

What I will do to this car is attach the trucks with brass screws, install Kadee couplers and draft boxes, add metal wheels, and properly weight the car with lead instead of the steel weight that comes with the kit.

Anyway, here goes....

Now, there are a few things I don't like about them, in particular the friction fit draft box lid, the friction pin used to hold the trucks on, the couplers, and the plastic wheels. I'm going to do a tutorial here, aimed primarily at beginners because you expert modelers probably have better ways to do this than I do, plus, I am pretty much a beginner myself. I hope I can give some good info concerning the tools, techniques, and materials used for modifying freight cars to others who are just entering the hobby. And, much of this tutorial can be applied to any of the lower end freight cars such as Life-Like, Athearn, and Roundhouse kits.

What I will do to this car is attach the trucks with brass screws, install Kadee couplers and draft boxes, add metal wheels, and properly weight the car with lead instead of the steel weight that comes with the kit.

Anyway, here goes....