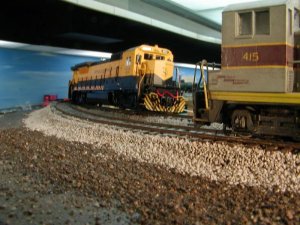

I just finished laying and wiring a new area of the layout and thought I'd post a couple shots. There is no scenery yet, just ballast. I actually posted a couple photos in the track planning thread then realized I should post a few here. The first local on the Garfield branch waits for the mainline freight to go by so it can enter the main.

New section in operation

- Thread starter Gary Pfeil

- Start date

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Oh..Suzy Q......

Always liked the "Q"'s paint scheme.

Looks like its coming along nice, Gary. Are you handlaying the track?

Always liked the "Q"'s paint scheme.

Looks like its coming along nice, Gary. Are you handlaying the track?

Gary thats some nice ballast and trackwork.

Are the point rails on your turnout's one piece. I've handlayed track in the past but think I'll go with flex track on my new layout and build the turnouts only.

t.

Are the point rails on your turnout's one piece. I've handlayed track in the past but think I'll go with flex track on my new layout and build the turnouts only.

t.

Thanks 88 and t, I've handlaid some of the trackage in this section, T, I am doing pretty much what you said you are going to do, handlay turnouts and use flex track elsewhere. My points are filed and bent to fit as one piece up past the frog. That's much easier than hinging them. The code 83 rail I used bends easily enough. Once its in place (I spike starting about 14 ties back from the points) I use a dremel cutoff disc to gap the frog. Before laying each rail, I use my Dremel drill press to drill a clearance hole for 20 gauge wire in the bottom, I solder the feed there. Each point has a feed, the frog has a feed, the stock rails have feeds. Operation is very smooth. I got a little carried away with one of the turnouts in this area. From point to frog is 13" on a 30" radius curve. Here is a photo. The gaps will be filled with styrene painted to match the rails.

Attachments

Gary those long sweeping curves look great though.

I've built straight one's but havn't attemped the curved type yet.

t.

I've built straight one's but havn't attemped the curved type yet.

t.

Nice workmanship there Gary.

I attemped to handlay track many years ago and found I just don't have the patience for it.

Nice work.

Marty

I attemped to handlay track many years ago and found I just don't have the patience for it.

Nice work.

Marty

Originally posted by NYCentral

I agree with Shamus, I wish I could make my own turnouts! Great job Gary!!

I've never made my own turnouts either. And I have no desire to. To call my soldering skills "skills" would be an injustice to the word.

You're doing a great job, Gary

Wow. it feels great to be complimented by such talented modelers! Casey, I build my turnouts primarily because I can tailor them to fit a situation. In this case. a passing siding running along a backdrop out of easy reach required turnouts which would be within easy reach. By locating this one near the middle of a turnback curve at the end of a peninsula, it is easy to get at. I wanted it to match the curve of the mainline precisely, the outer route being a 30" radius, the inner only slightly smaller, thus the long points. BTW, there is no great amount of soldering involved, other than feeds, which all track requires anyway. Quite a bit of filing though! They don't have the fine details that some of the better commercial turnouts have, but they work great.

T, there is really no difference in building curved versus straight turnouts. I never work with a fixed frog #. After laying out the centerlines for each route and gluing down ties, I lay the stock rails first, filed to accept the points later. Then I file the frog points on two lengths of rail and use the NMRA gauge to locate where the point of the frog should be. When done this way it makes no difference what degree of radius you use. And you get nice flowing turnouts.

Gary

T, there is really no difference in building curved versus straight turnouts. I never work with a fixed frog #. After laying out the centerlines for each route and gluing down ties, I lay the stock rails first, filed to accept the points later. Then I file the frog points on two lengths of rail and use the NMRA gauge to locate where the point of the frog should be. When done this way it makes no difference what degree of radius you use. And you get nice flowing turnouts.

Gary

ballast

Hi Gary...just wanted to say "beautiful job" so far and glad things are progressing nicely.

Wanted to see if you could fill us (me ) in on the ballast your using...what brand? why the different colorations? Is it NYC prototypical for the era your modeling? etc. etc. etc.

) in on the ballast your using...what brand? why the different colorations? Is it NYC prototypical for the era your modeling? etc. etc. etc.

As you know, I'm modeling NYC operations also and though, I'm not there yet in respect to the ballast, I'de like to plan ahead in what type and colors I'll need for the near future.

Thank You!!

Matt--Hershey, Pa.

Hi Gary...just wanted to say "beautiful job" so far and glad things are progressing nicely.

Wanted to see if you could fill us (me

As you know, I'm modeling NYC operations also and though, I'm not there yet in respect to the ballast, I'de like to plan ahead in what type and colors I'll need for the near future.

Thank You!!

Matt--Hershey, Pa.

Hi Matt, The ballast is Woodland Scenics light grey in medium and fine. It doesn't have anything to do with NYC ballast, although when I relay the four track section(only 2 tracks now, code 100 Atlas) I will attempt to recreate the white ballast I've seen in many photos along the river. This apparently got darker from weathering not to long after being spread, but I like the looks of it and have one or two photos I will use to guide me there. The different coloration in the photos is due to two factors: The fine ballast took coloration more readily than the medium, and the ballast was applied in two sessions, one prior to laying rail, and one after. The wetting/coloring solution (ala Charlie) was stronger the first time around. Not by intention but it works out ok. I am not finished with the track painting yet.

You should look at color photos of the area (west of Buffalo, right?) and era you're modeling and see what the ballast looks like. How is your layout coming along?

Gary

You should look at color photos of the area (west of Buffalo, right?) and era you're modeling and see what the ballast looks like. How is your layout coming along?

Gary

Thanks for the info. So far i have penciled in three curved turnout's on the first of three sections that will make up the layout. And each time mumbled obsenities to myself. but I'm going to give it a try.

t.

t.

Great workmanship Gary. Talk about inspiring. I tried to make some turnouts years ago with little success but now after seeing your results makes me want to do it again.

Thanks

Thanks

I lay the stock rails first, filed to accept the points later. Then I file the frog points on two lengths of rail and use the NMRA gauge to locate where the point of the frog should be. When done this way it makes no difference what degree of radius you use. And you get nice flowing turnouts.

Gary,

First, I can attest to the operation of your hand laid turnouts. Not one problem, all evening!

Then, it was nice to see the SM&CH boxcar in the background, Thanks. There was a JGL hopper running at Trainfest, and, I hope Tyson sees this, There was a Nantahala Midland box car there too.

Pete

Originally posted by Gary H Pfeil

You should look at color photos of the area (west of Buffalo, right?) and era you're modeling and see what the ballast looks like. How is your layout coming along?

Gary: All I've been able to find are black and white photos on the web though I'm sure there are books out there that may have color pics. I'm really pleased with the way mine is coming along as well. (No handlaid track for me at this stage of my career)

Lower level mainline trackage is complete. All double checked for NMRA standards, sections soldered and trains test ran back and forth a zillion times to ensure NO DERAILMENTS!!!! The lower level needs to be especially bulletproofed due to the accessability not being "easy". I'll be putting up some "safety netting" and ironing out a couple of kinks in the next day or so before progressing on to the staging/passing siding on the lower level.

I'll post some pics IF Santa brings me my digital cam for Christmas!!!

(I think I've been especially good this year!!

)

Matt--Hershey, Pa.

Robin, Thanks. Somewhere back in Tech Questions I wrote about handlaying, basically I use Tony Koesters method which appeared in an old MR and was reprinted in a book I believe. Really simple once you know how (like everything else in life!) It is a bit tedious, as marty pointed out.

Pete, Your car is featured more prominently (and noted) in a photo in the trackplanning thread Thoughts behind the design of the JGL. Also what I thought was the best photo of the Suskie units on the curve.

Gary

Pete, Your car is featured more prominently (and noted) in a photo in the trackplanning thread Thoughts behind the design of the JGL. Also what I thought was the best photo of the Suskie units on the curve.

Gary