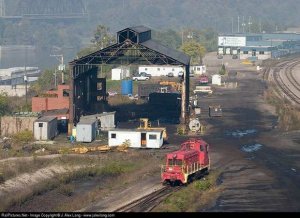

This is on my N-Trak module. I'm constructing a scene of a metal fabrication facility. This is the superstructure for the overhead crane, just mocked up. I'd like to use the plastic base plates for it to keep the structure unitized, as this bit is rather flimsy and I'll probably remove it for transport. The issue is the track height...I have it glued to cork. Normally, it would just be ballasted. But this places the track height significantly higher than the surrounding ground. I'm not sure it would look right. Most 1:1 facilities have the track at 'ground' level but I couldn't figure out a graceful way to drop the track off the cork, and at this stage I'm not tearing it up.

Some of the thoughts I've had are just leaving it as-is (the easy way out) and ballasting it. Also considered plastering it level with the tracks and having it as sort of a raised loading dock with a ramp for trucks to access it. The problem with this is I've already ballasted the mainlines (adjacent) and there isn't much wiggle room on the side furthest away in the photo to build it up. To the left of the photo will all be gravel parking lot.

I suppose I could build up a mound and just gravel it instead of going for a concrete look, and use the plastic base as the cement 'pad' for the structure.

Just trying to make it look as realistic as possible. Give me your thoughts, to be used or discarded as I see fit.

Some of the thoughts I've had are just leaving it as-is (the easy way out) and ballasting it. Also considered plastering it level with the tracks and having it as sort of a raised loading dock with a ramp for trucks to access it. The problem with this is I've already ballasted the mainlines (adjacent) and there isn't much wiggle room on the side furthest away in the photo to build it up. To the left of the photo will all be gravel parking lot.

I suppose I could build up a mound and just gravel it instead of going for a concrete look, and use the plastic base as the cement 'pad' for the structure.

Just trying to make it look as realistic as possible. Give me your thoughts, to be used or discarded as I see fit.