I will have to look into Depron. I'm still capable of learning new tricks, it just takes longer with fewer neuronswall1

I forgot to mention my most important design tool - MS Excel. All the cross section data are put into Excel spreadsheets and macros compute the 2-D patterns. These are usually smooth these a bit with some statistical software.

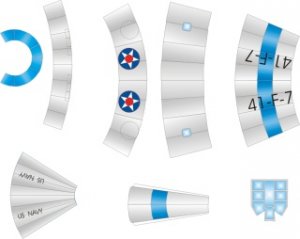

A few more pics (I haven't looked at some fer years now). The f-15 was commissioned as a retirement "card" for an engineer who worked on the Program for the USAF. The simplest design I done in years, glides well if slingshot launched. Needs tiny ducted fans!

I forgot to mention my most important design tool - MS Excel. All the cross section data are put into Excel spreadsheets and macros compute the 2-D patterns. These are usually smooth these a bit with some statistical software.

A few more pics (I haven't looked at some fer years now). The f-15 was commissioned as a retirement "card" for an engineer who worked on the Program for the USAF. The simplest design I done in years, glides well if slingshot launched. Needs tiny ducted fans!