Heya all,

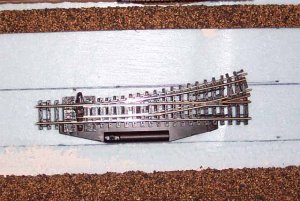

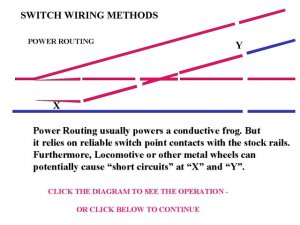

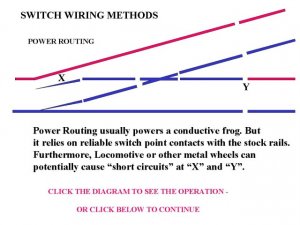

I picked up some Peco Streamline Universal medium switches today. My LHS said PECO was the best so I went that route. However, I get home and am trying to sketch out a simple passing crossover onto my foam and have come up with some complications. According to the instructions in step 2 (picture 1), you simply butt them up end to end and your done. The Kato track spacing guide recommends ideal track centerline spacing to be 1-5/16"s apart as measured by my black lines drawn on the blue foam. If I do this according to the Peco instructions, I only get 1-1/16"s apart (picture 2). Yes, I know that one of the switches is upside down...for layout purposes, that should not matter. If I move them to the correct centerline spacing apart, I end up with this big old gap in between them that is going to have to be filled by a little tiny piece of filler track - what a pain (picture 3). My older Atlas switches don't have this problem (picture 4) because they have a slighly tigher radius and a slightly longer track that you can just barely make out in picture 5 when I overlay one on top of the other.

I don't want to use the Atlas switches but I will if I have to in order to get around this problem. Does Peco make a little filler piece of track to compensate for this or what's the deal? Anybody else come across this and how did you fix it?

I picked up some Peco Streamline Universal medium switches today. My LHS said PECO was the best so I went that route. However, I get home and am trying to sketch out a simple passing crossover onto my foam and have come up with some complications. According to the instructions in step 2 (picture 1), you simply butt them up end to end and your done. The Kato track spacing guide recommends ideal track centerline spacing to be 1-5/16"s apart as measured by my black lines drawn on the blue foam. If I do this according to the Peco instructions, I only get 1-1/16"s apart (picture 2). Yes, I know that one of the switches is upside down...for layout purposes, that should not matter. If I move them to the correct centerline spacing apart, I end up with this big old gap in between them that is going to have to be filled by a little tiny piece of filler track - what a pain (picture 3). My older Atlas switches don't have this problem (picture 4) because they have a slighly tigher radius and a slightly longer track that you can just barely make out in picture 5 when I overlay one on top of the other.

I don't want to use the Atlas switches but I will if I have to in order to get around this problem. Does Peco make a little filler piece of track to compensate for this or what's the deal? Anybody else come across this and how did you fix it?