webmaster said:Hmmm... In that case, are the two rods fixed together permanently (rigid)? Obviously the one one the disc rotates, but I must be missing something otherwise the two arms if not fixed rigid will it not just rotate without a lift?

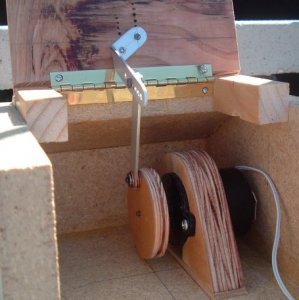

They are not rigid, they pivot at the point where the two connect. Look at the exploded pic of the linkages and you'll see two small brass bearings cut from tubing. They are slightly wider than the thickness of the rods and their washers. When tightened, the fasteners compress on the bearings in a way that keeps the arms free moving without being sloppy. While the bearings are my own design, there is a pic in the article that shows how the arms themselves work but I don't believe I can post that.