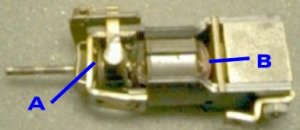

I think that you've probably got the solution to your problem with the excess play in the armature - some thrust washers at either or both ends should help with that problem. The brushes should be centred, lengthwise, on the commutator. The screw holding the motor in place should be tight, to prevent the motor from moving. Then, if necessary, use paper or cardstock, placed under the motor, either under its entire length or at one end or the other, to achieve the optimum gear mesh. The gear teeth should not bottom-out in the other gear - tight gear mesh places an extra load on the motor and is noisier, while an excessively loose mesh will also cause vibration (which translates to noise). However, a gear mesh slightly too loose is preferrable to one too tight. Don't forget, too, to lubricate those gears with a suitable plastic-compatible oil such as LaBelle #102.

Wayne