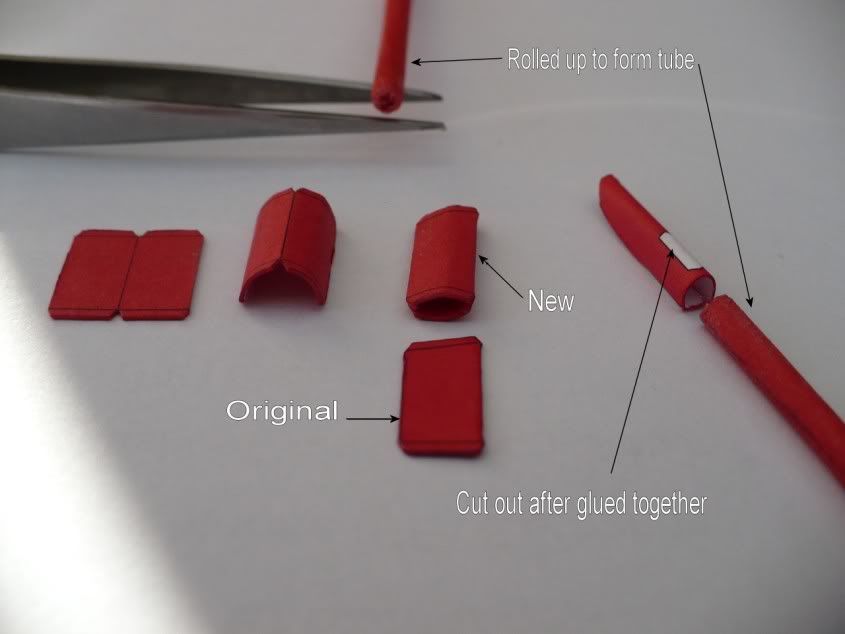

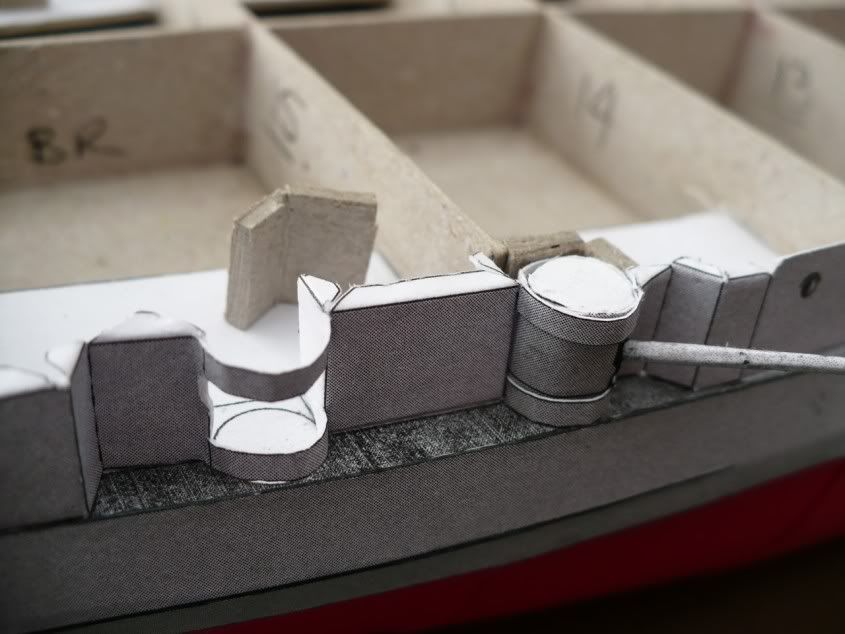

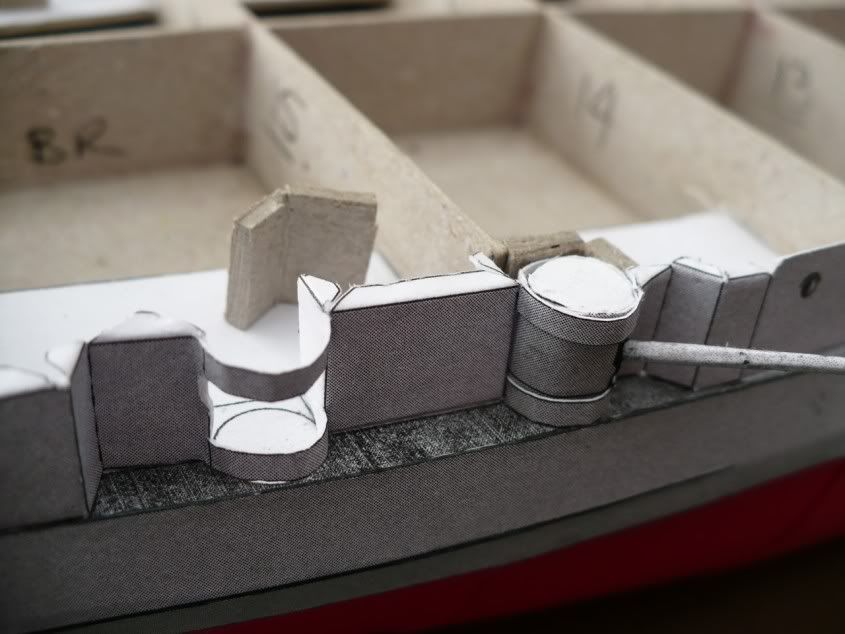

I also wanted the 138mm gun turrets to swivel.

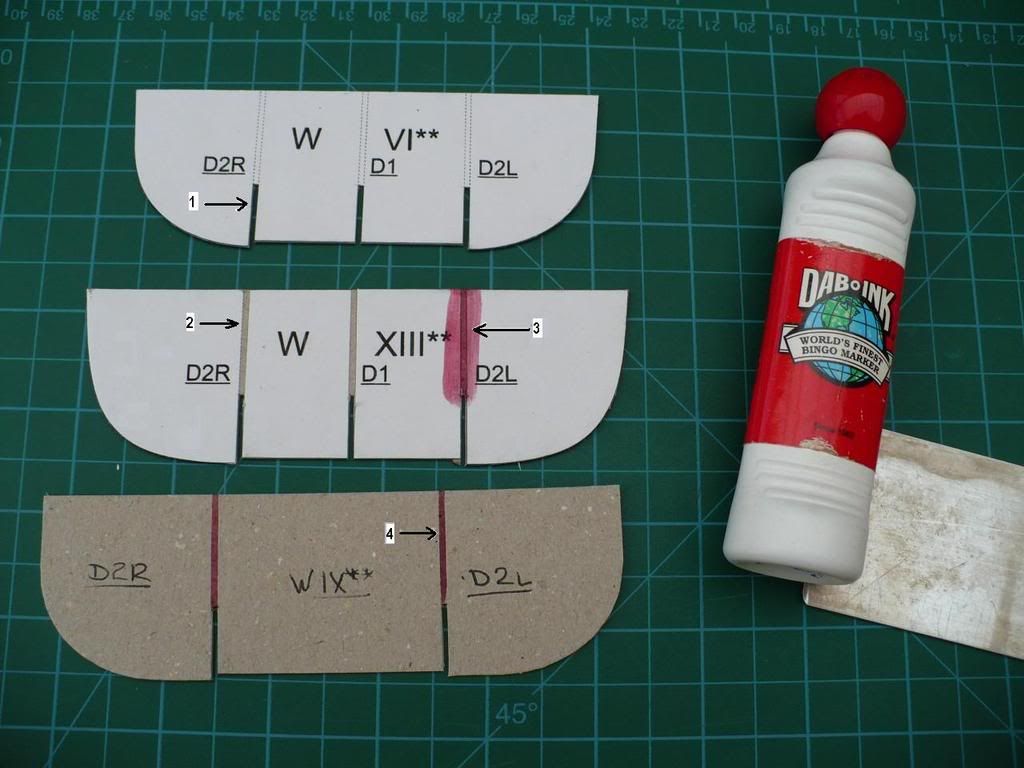

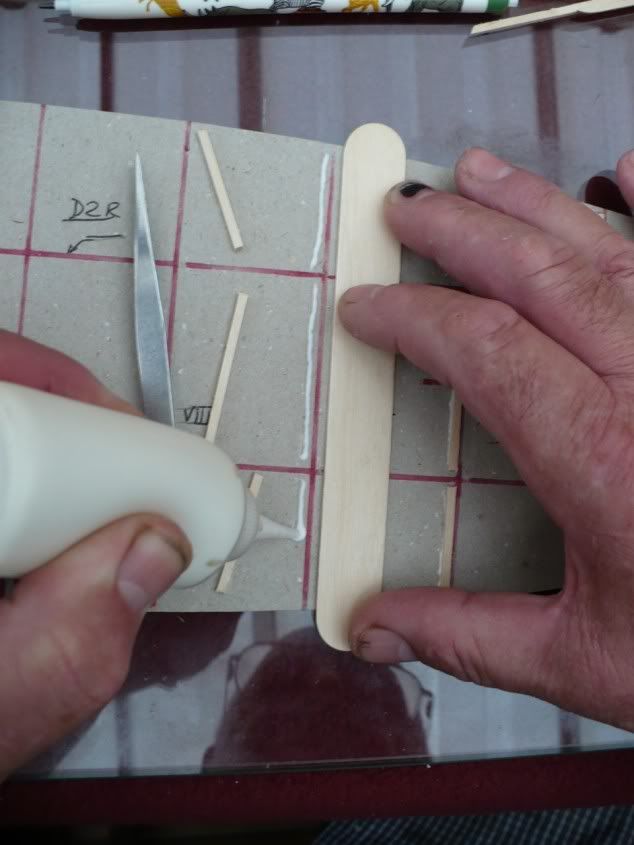

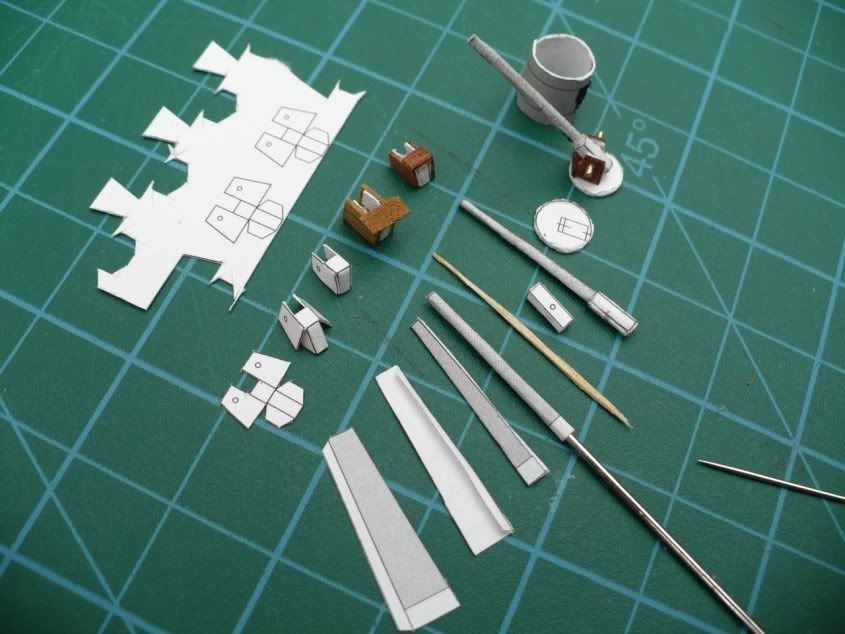

The instructions say to put pins in the centres of the top and bottom of the turrets to enable them to swivel but this would have been a mission to align the deck when gluing it over the turrets. A far easier and simpler solution was to make a “cage” from thick card around the rear of the turret. This worked great and the turrets swivel perfectly.

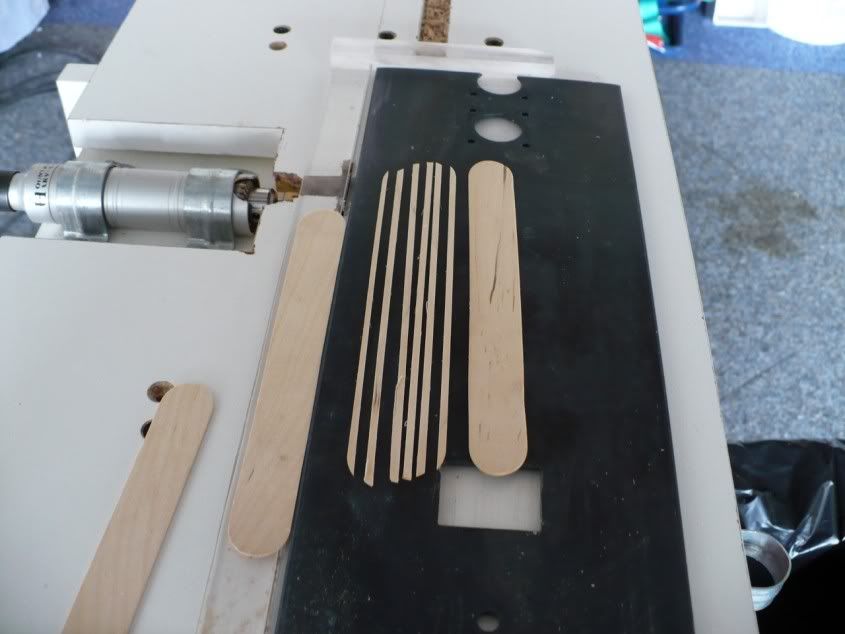

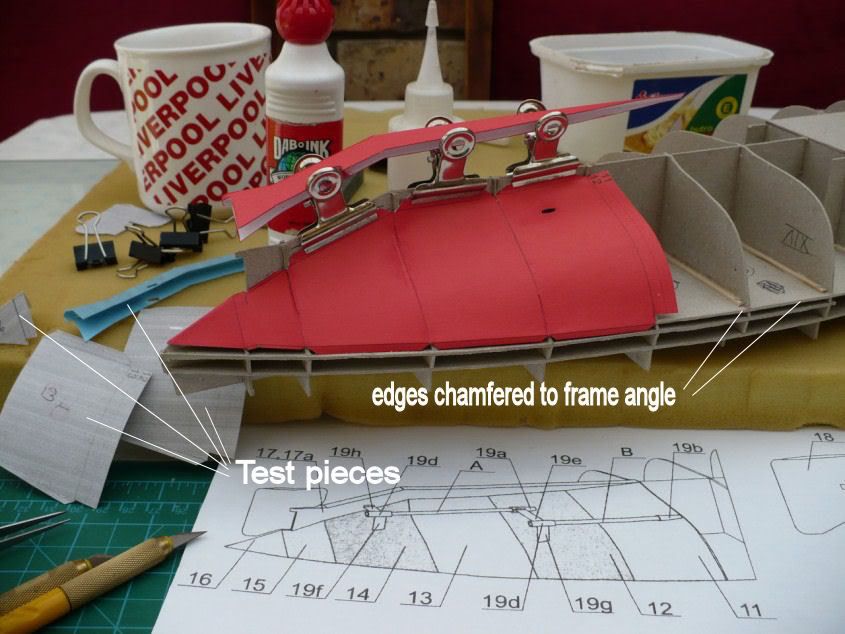

I am also beginning to find that some parts need “tuning” to fit. The bands around the turrets nearest to the centre of the ship on both sides were not long enough and I had to make new ones from one of the spare pieces of coloured card supplied. Also, the frames under the rear deck came flush to the edge of the deck but the frames under the forward deck were not wide enough so the deck overhung the frames along each side. The hull sides were supposed to glue to the frame edges and the deck edge and finish level with the top surface of the deck. This was solved by gluing small squares of card against the frame edges to bring them flush with the edge of the deck. The hull sides were then glued to these packing pieces and the deck edge.

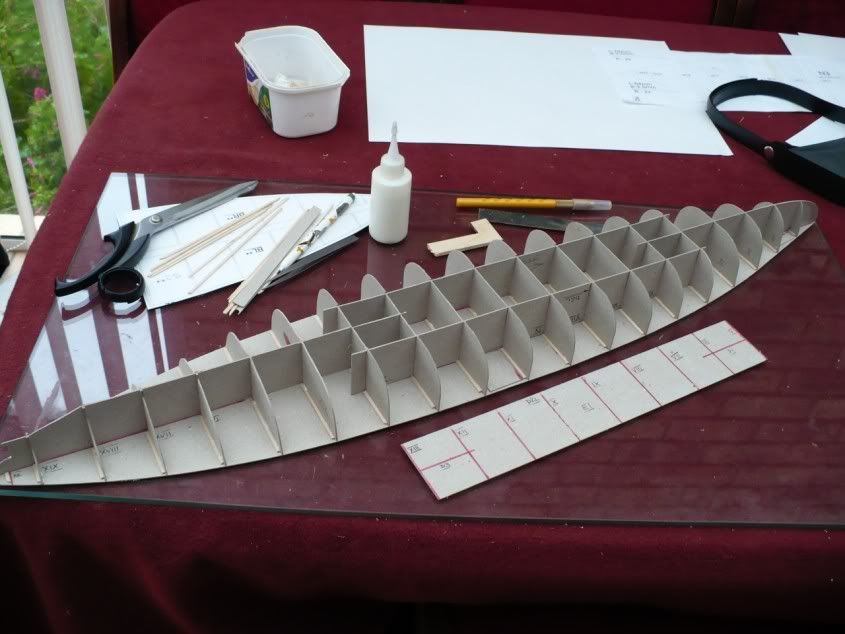

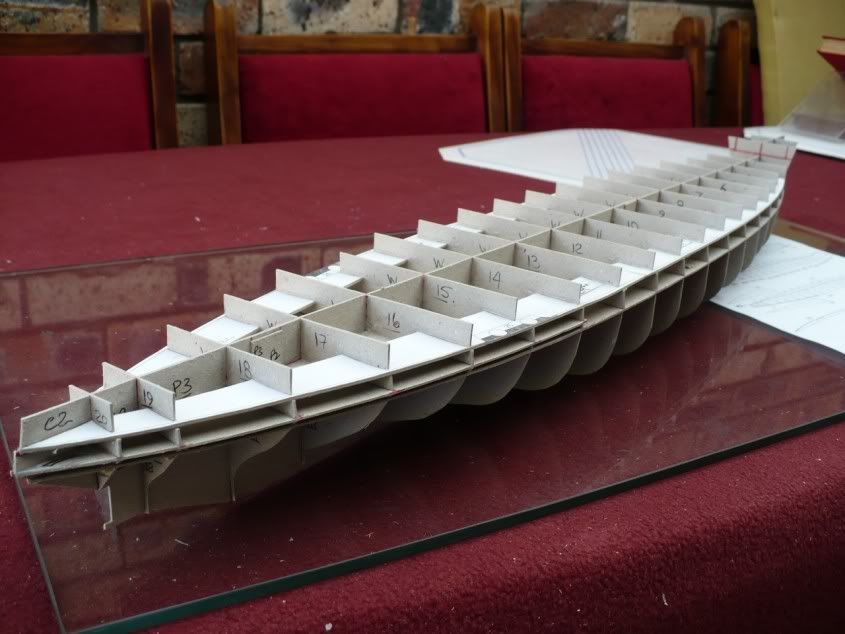

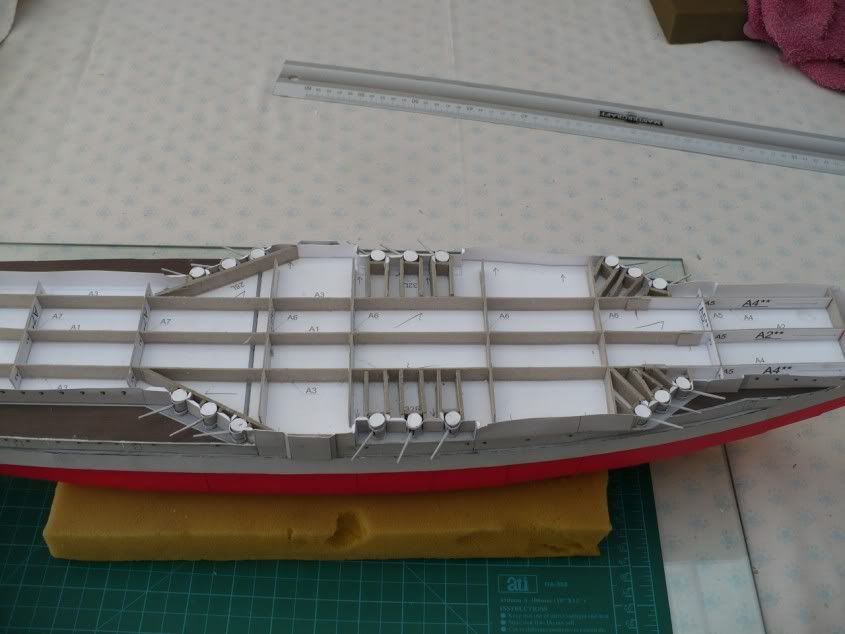

Here is the completed hull with first deck in place forward.

Normally, I assume the deck should go on first and then the sides are glued to it and the supporting frames. On this model however, because of the 138mm gun turrets recessed under the decks, the side pieces have to go on first and then the deck fitted afterwards.

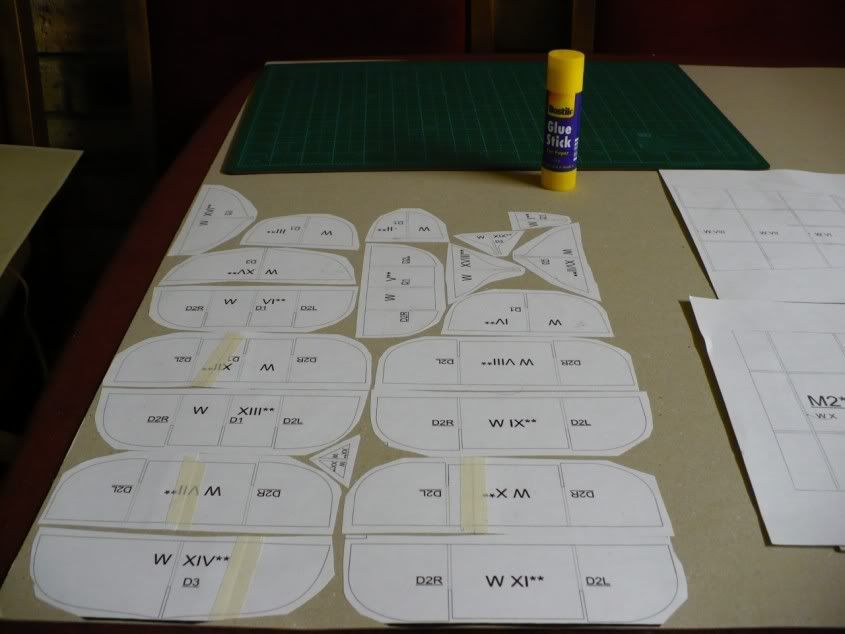

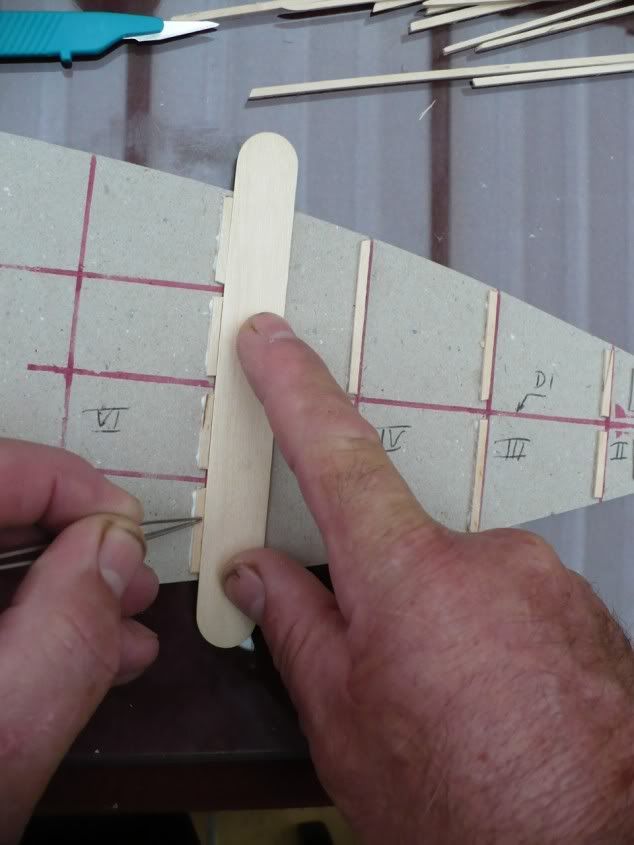

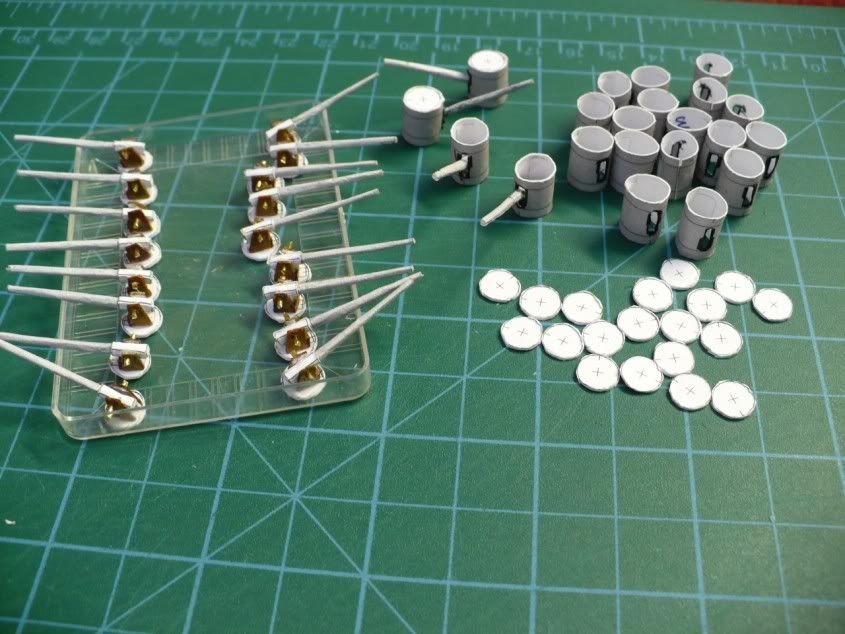

Lower deck 138mm gun turret positions

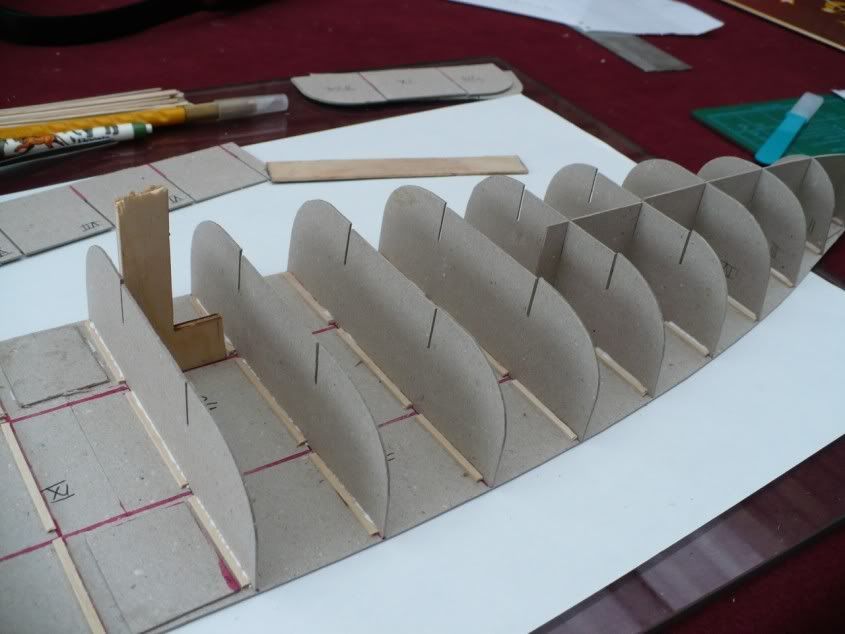

Upper deck 138mm gun turret positions.

Upper deck gun cages.

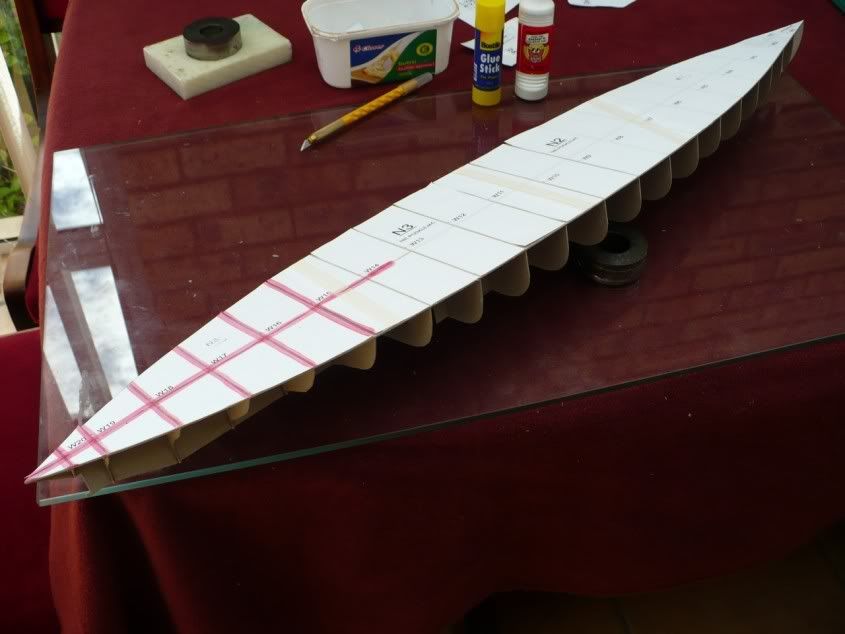

The decks were such a tight fit that they had to be “sprung” into position. This was done by bending the card decks along the centre axis to give a serious camber to the decks. This meant that the deck width was then less than the distance between the sides. PVA was then applied to the deck supporting frames and hull side edges and the deck sprung into place. The deck was then weighted with food tins to flatten it so that it fitted against the sides and was in contact with the supporting frames underneath.

Here is the fore deck fitted.

And finally, the completed hull.

I have come to the conclusion that card modellers are masochists!