I am joining my existing layout, which is hinged and can swing open, to a fixed base addition. I know some of you have layouts that include a swing "bridge" to allow you easy access to inside a wrap-around layout and I'm wondering what method you might use to couple the movable track to the fixed track so that they are aligned and don't cause problems when running trains over them. Or do you rely strictly on getting them just close enough and hope they stay in alignment each time you open and close the bridge?

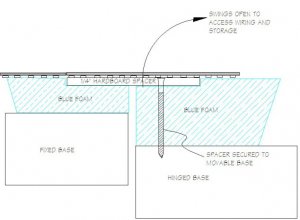

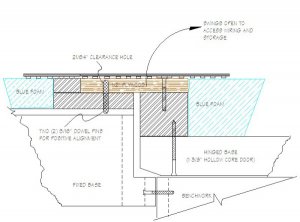

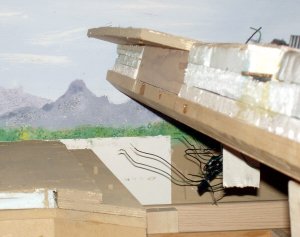

This sketch kinda gives you and idea of what I had in mind. The movable section is attached to the fixed section except that the top swings open. I'm using the 1/4" spacer to stiffen the movable end and to hide the gap between the movable and fixed ends.

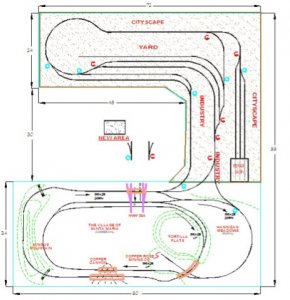

This is N scale, and I have three tracks that are going to bridge between these sections. The second sketch is an overall view of my old and new layout plans. Any help as to what others have done, or any thoughts at all as to how to approach this will be appreciated.

This sketch kinda gives you and idea of what I had in mind. The movable section is attached to the fixed section except that the top swings open. I'm using the 1/4" spacer to stiffen the movable end and to hide the gap between the movable and fixed ends.

This is N scale, and I have three tracks that are going to bridge between these sections. The second sketch is an overall view of my old and new layout plans. Any help as to what others have done, or any thoughts at all as to how to approach this will be appreciated.