Hi All,

I have decided to give this little Russian Battleship in the round a try. I purchased the Gremir Models version of it a couple of years ago and it has been languishing, stashed away in my hard drive. It is a 1/200 scale model, my favorite ship scale at the moment.

For those of you not familiar with the ship, it was designed by Admiral Andrey Alexandrovich Popov and construction was started on December 17, 1871 in the New Admiralty Shipyards in Petersburg.

The idea was to provide as stable a platform for a pair of 280mm muzzle loading cannon as could be provided in a coastal battleship design with the maximum amount of armor for protection. To that end the ship had six propellers powered by six individual steam power plants. These were laid out three to an engine room on either side of the hull, taking up most of the below decks area. She sported 12 keels on her hull bottom in an attempt to provide directional control in operation. Unfortunately in actual use, even with 12 keels it required full opposite rudder in relation to the direction of gunfire to keep the ship from rotating with each shot. The round hull design pitched and rolled in even moderate seas despite all the attempted stabilization and power. So it was pretty much a bust, even so they built a second one and it was named after the designer as "Rear Admiral Popov". The pair of them became known as the "popovkas". They did see service in the Russo Turkish War serving in the Danube Flotilla. Unfortunately while in service there, it was discovered that they were vulnerable to plunging fire from high angle artillery despite the heavy side armor they sported. In 1903 they were converted to store ships and in 1912 finally decommissioned and scraped.

The first thing I noticed about the sheets of parts that provide the framework for the model is that all of these parts are to be laminated up to 1.5mm in thickness. Three sheets laminated together of the 110 pound cardstock I printed it out on provides 1mm so I guess a couple more will be required to get close to that mark. I am using Krylon Spray Adhesive to laminate the sheets together. I am also going to try something new for me for this model, using some of Krylon's Preserve It, Ultraviolet proof spray to stabilize the colors over the long term and hopefully act as a sort of plasticizer to the card. I have heard from other modelers that this makes cutting sharp edges easier and helps to prevent bleeding of edge coloring. I use Faber-Castell Pitt Pens for most of my edge coloring, but sometimes for some colors I have to use my collection of Sharpie markers and these do bleed, even with 110 pound cardstock.

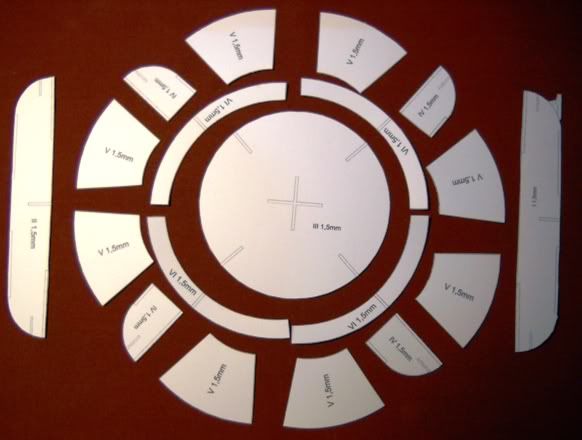

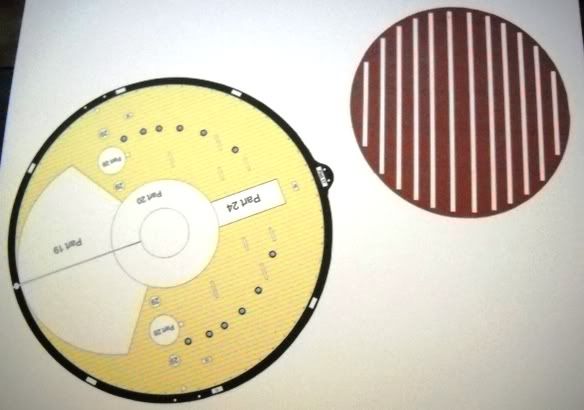

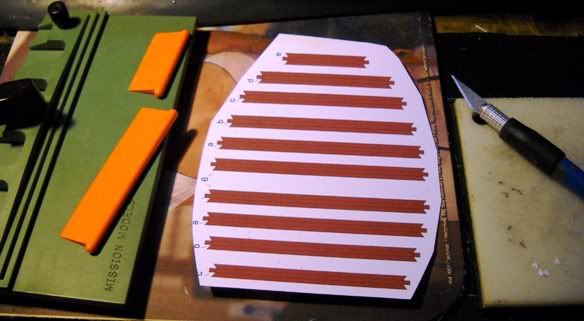

Here is a shot of the parts as they dry from the Preserve It spray job so you can see what I have to start with for this one.

I have decided to give this little Russian Battleship in the round a try. I purchased the Gremir Models version of it a couple of years ago and it has been languishing, stashed away in my hard drive. It is a 1/200 scale model, my favorite ship scale at the moment.

For those of you not familiar with the ship, it was designed by Admiral Andrey Alexandrovich Popov and construction was started on December 17, 1871 in the New Admiralty Shipyards in Petersburg.

The idea was to provide as stable a platform for a pair of 280mm muzzle loading cannon as could be provided in a coastal battleship design with the maximum amount of armor for protection. To that end the ship had six propellers powered by six individual steam power plants. These were laid out three to an engine room on either side of the hull, taking up most of the below decks area. She sported 12 keels on her hull bottom in an attempt to provide directional control in operation. Unfortunately in actual use, even with 12 keels it required full opposite rudder in relation to the direction of gunfire to keep the ship from rotating with each shot. The round hull design pitched and rolled in even moderate seas despite all the attempted stabilization and power. So it was pretty much a bust, even so they built a second one and it was named after the designer as "Rear Admiral Popov". The pair of them became known as the "popovkas". They did see service in the Russo Turkish War serving in the Danube Flotilla. Unfortunately while in service there, it was discovered that they were vulnerable to plunging fire from high angle artillery despite the heavy side armor they sported. In 1903 they were converted to store ships and in 1912 finally decommissioned and scraped.

The first thing I noticed about the sheets of parts that provide the framework for the model is that all of these parts are to be laminated up to 1.5mm in thickness. Three sheets laminated together of the 110 pound cardstock I printed it out on provides 1mm so I guess a couple more will be required to get close to that mark. I am using Krylon Spray Adhesive to laminate the sheets together. I am also going to try something new for me for this model, using some of Krylon's Preserve It, Ultraviolet proof spray to stabilize the colors over the long term and hopefully act as a sort of plasticizer to the card. I have heard from other modelers that this makes cutting sharp edges easier and helps to prevent bleeding of edge coloring. I use Faber-Castell Pitt Pens for most of my edge coloring, but sometimes for some colors I have to use my collection of Sharpie markers and these do bleed, even with 110 pound cardstock.

Here is a shot of the parts as they dry from the Preserve It spray job so you can see what I have to start with for this one.