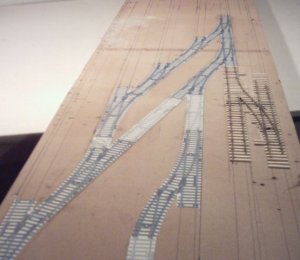

Here is how I did it when I build my N scale track.

As you can probably see from the pictures, I solder the track to PC ties (printed circuit board ties from Clover House). So first I glue the ties down on top of either the bare plywood or cork roadbed. I used regular white glue, but would probably recommend the yellow carpenters glue as it doesn't dissolve in water. I did have a few places on curves where the track would shift or move a little bit when I ballasted because the white glue got dissolved with the water. It was a simple fix, just put some weight on top of the rail until the ballasted area is dry.

Anyway, you put down the ties, let the glue dry completely, then you lightly sand the wooden ties as they are higher than the pc ties, be careful not to sand too much as you will start sanding the pc tie and remove the copper from them. It's not as difficult as it might sounds, just requires a little practice.

Now after the ties are sanded and the ties are smooth and even, you can lay your first rail. I made a small template from a piece of styrene with a gap which would fit over the tie and with a mark of where to place the rail, this is not necessary, but I found it to be an easy way to get the rails 'centered' correct on the ties.

Start with a straight section as that is the easiest. Solder the rail in one end, with a straight edge (I have a 4' straight edge) locate the position of the other end of the rail and solder it, now solder the rail to the remaining pc ties, but don't solder all in one go as the rail (C40 anyway) will expand quite a bit when heated, so I usually soldered maybe every 4th pc tie, waited a bit, went back, solder every 4th again and so on, I found this way to work quite well. Done with the first rail, and happy with it's position and flow (when on curves), attach the other rail using 3 point gauges (from ME) and your NMRA gauge.

After just a little bit of practice you are ready to build a turnout. As TC mentioned, I too build the turnouts in place, and there are lots of places on the net that describes how to build them, so my only advise is to 'go ahead, try it' and don't give up if you have to trash or redo the first one, I did that too, but the second came out better, and suddenly it was possibly to build a turnout in about 1 1/2 hour or maybe even less sometime.

hope this helps

Jesper