Thanks folks.

I heard that American people are kind. Now I realize you are the kindest people I have ever met since I was born.

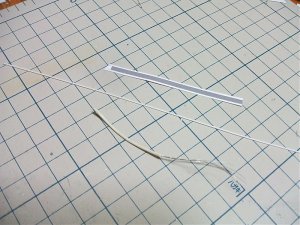

Discoloring of the sections I made long time ago were significant and they were obviously different from newly built section. So, I came up with the silly idea of painting it with diluted water color sneakingly so that no body would be aware of it but it was huge mistake, fiasco. After painting water color, surface of the card becomes not smooth.

Today I went out to take picture of the model outside for the purpose of testing under what lighting my fiasco does not stand out.

BTW after taking pictures I was aware one small boat was missing. Not only boats but also some of structures I have not glued for the future workability. I thought it must have dropped somewhere on the paving. Boat was so tiny that I was not able to find it out easily. Finally I had to crawl around and about 30 minutes later I found it out then picked up. When I stood up, I caught the eye of neighbor's wife. Obviously she was trying to keep a straight face and asked me "Found out?" and I replied "Yes" then she burst out into laughing:cry:

I heard that American people are kind. Now I realize you are the kindest people I have ever met since I was born.

Discoloring of the sections I made long time ago were significant and they were obviously different from newly built section. So, I came up with the silly idea of painting it with diluted water color sneakingly so that no body would be aware of it but it was huge mistake, fiasco. After painting water color, surface of the card becomes not smooth.

Today I went out to take picture of the model outside for the purpose of testing under what lighting my fiasco does not stand out.

BTW after taking pictures I was aware one small boat was missing. Not only boats but also some of structures I have not glued for the future workability. I thought it must have dropped somewhere on the paving. Boat was so tiny that I was not able to find it out easily. Finally I had to crawl around and about 30 minutes later I found it out then picked up. When I stood up, I caught the eye of neighbor's wife. Obviously she was trying to keep a straight face and asked me "Found out?" and I replied "Yes" then she burst out into laughing:cry: