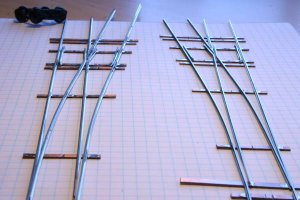

Fast Track Hand Laid Turnout Jigs.

http://www.handlaidtrack.com/item.php?id=1253&link_str=215::270::277&partno=AK-HO-T-6-ME83

I'm curious as to what you gents think about these things. There must be some sense of accomplishment to being able to handlay your own track and truely make your layout unique.

As far as cost factor, is there any real benefit to this method of construction? After the initial start-up fee of course, in the long run, is there really any savings? Or am I wasting my time even considering this? The way I figure, if you are only making say two or three turnouts, then you'd be better off just buying the prefab ones and going on your way. However, if say you needed or had plans to do a batch, like 10-20 plus over the long term, then perhaps, if you have the inkling, the confidence, the time and a steady hand this could be an alternative.

The only reason I ask as well as it will be sometime before I start actual construction and maybe banging off a couple of these once in awhile will keep me motivated, until I'm ready to start my actual building.

Yes, I'm an ambitious bugger who isn't afraid to try new things.

http://www.handlaidtrack.com/item.php?id=1253&link_str=215::270::277&partno=AK-HO-T-6-ME83

I'm curious as to what you gents think about these things. There must be some sense of accomplishment to being able to handlay your own track and truely make your layout unique.

As far as cost factor, is there any real benefit to this method of construction? After the initial start-up fee of course, in the long run, is there really any savings? Or am I wasting my time even considering this? The way I figure, if you are only making say two or three turnouts, then you'd be better off just buying the prefab ones and going on your way. However, if say you needed or had plans to do a batch, like 10-20 plus over the long term, then perhaps, if you have the inkling, the confidence, the time and a steady hand this could be an alternative.

The only reason I ask as well as it will be sometime before I start actual construction and maybe banging off a couple of these once in awhile will keep me motivated, until I'm ready to start my actual building.

Yes, I'm an ambitious bugger who isn't afraid to try new things.