PROTO 1000 Sound decoder "Hardwire" install

BEFORE WE BEGIN...

I am going to show you folks how

I do a "Hardwire" install.

What is a "Hardwire" install?

A "Hardwire" install is wiring a decoder, or in this case a sound decoder, into an engine.

We will be doing the hardwire installation because the engine that is getting the sound decoder DOES NOT have a DCC READY "Plug-n-Play" circuit board.

Though i am installing the sound decoder in a Proto 1000 engine, you can use this

same exact type of install on ANY engine thats motor is already isolated from the frame, and does NOT have a Plug-n-play circuit board:winki: .

HOWEVER, you can use this type of install on "DCC ready" engines with plug-n-play circuit boards too, take Athearns "DCC ready" engines for example, their plug-n-play circuit boards are worthless:eeki: (in MY eyes), and i hardwire ALL my sound decoders into those engines. (i have wrote SEVERAL posts on this:winki: )

ANOTHER REASON to do a hardwire install would be to save space, in many engines there just isn't much room to add a sound decoder, so to save space you might need to take out the existing circuit board thats in the engine to give you room to install the sound decoder:winki: .

A SMALL DISCREPENCY...

I am installing a sound decoder into an FM CPA16 engine, Loksound makes real good quality sound decoders, thats sounds are really pretty much "right on" for the engine sound they offer:thumb: . the problem i am having with this engine is i use 6 resources to get my sound decoders from, and only one of the six had Loksound FM sound decoders in stock, the two FM sound decoders i had to choose from was the H10-44 and the H24-66 sounds, no CPA16/CFA16 sound decoders were available. i wanted to stay with the FM opposed piston sound, so i opted for the H24-66 sounds, its not right for this engine, but at least it has the FM opposed piston sounds:winki: .

LETS BEGIN THE INSTALL... :twisted:

TOOLS NEEDED:

Soldering gun

solder

hot glue gun

4'' piece of fine black wire

4" piece of fine red wire

thin strip of thick styrene

wire cutters

exacto knife

heat shrink tape

electrical tape

ALSO, the decoder or sound decoder of your choice, a set of DCC compatible lights, and of coarse, the engine to install it all in:toug::119: .

OK, now that we have ALL the materials together that we need, this install should only take 30-45 minutes, tops:thumb: .

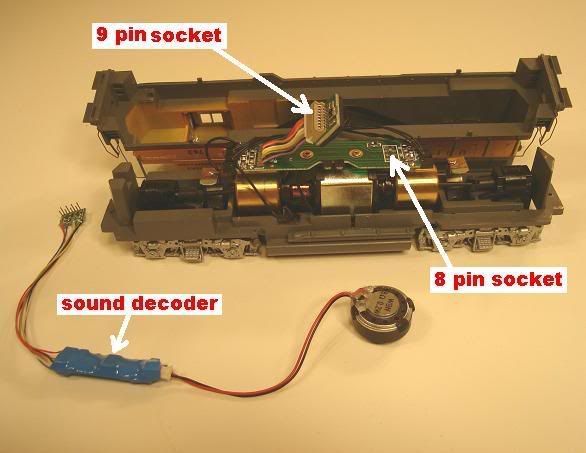

get your engine and sound decoder out, and familiarize your self with them...

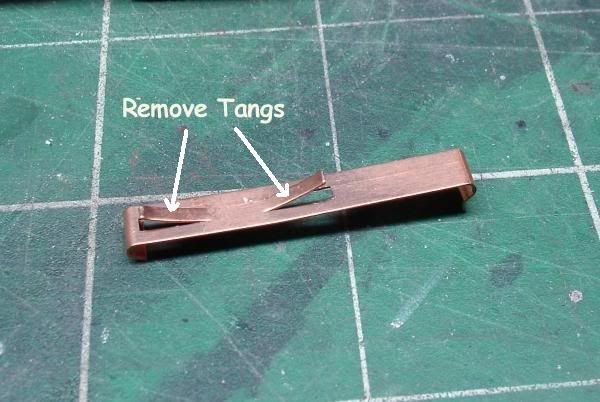

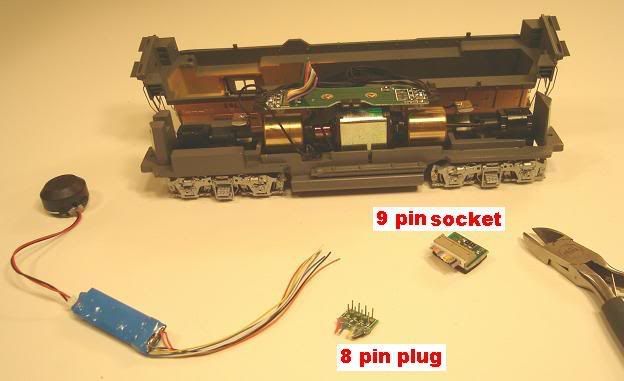

Now, cut the 8 pin plug off your sound decoder, exactly as i shown in the pic below, leaving plenty of wire still attached to the sound decoder...

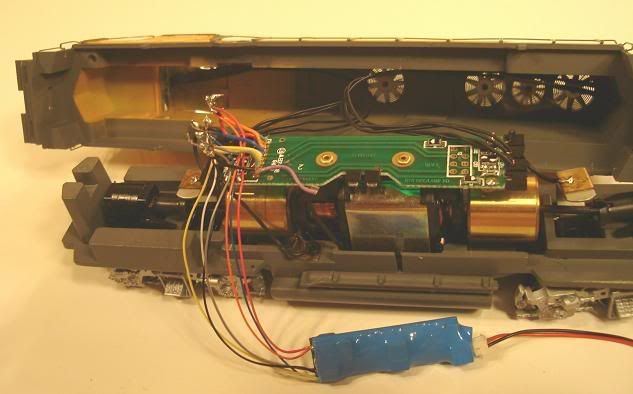

NOW disconnect the wires from the circuit board thats in the engine, and pull the circuit board out of it, also take the light/s out of the engine at this time...

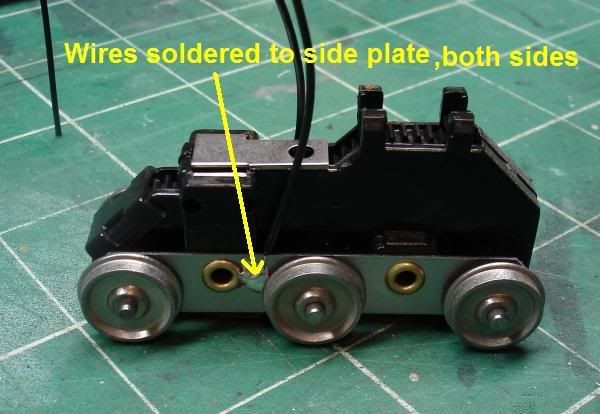

Now you see the only wires that are still in the engine are the four wheel power pick up wires, two red, two black, and the two engine power wires in the middle of the engine, one black, one red. (pic below)

At this time i make a little "shelf" out of a thick piece of styrene, what this does is gives you something to put the speaker and sound decoder on so none of it touches the hot motor, and it keeps the wiring from getting into the gears:winki: . i put two SMALL drops of hot glue on top of the flat part of the motor casing, let the glue almost dry, then put the styrene "shelf on it, DON'T press the shelf down hard on the motor, the drops of hot glue keep the "shelf" off the motor just a bit so air can get between the two, for cooling purposes:winki: . MAKE SURE THE SHELF TOUCHES NO MOVING PARTS.

OK, NOW we are going to take the two pieces of 4'' wire we have(red and black), and we are going to make them "jumper wires" that will go between the left and right side wheel power pick up wires. (shown below)

**NOTE: YOU WILL WANT TO USE YOUR HEAT SHRINK TAPE TO COVER THE SOLDERED WIRES WHEN YOUR DONE, you will notice i don't use the heat shrink tape, i hot glue over my connections:eeki: , it does the same thing as heat shrink tape, but you have to be VERY CAREFUL and make sure ALL of the bare wire is covered, I DO NOT RECOMMEND doing as i do, PLEASE USE the heat shrink tape, WHY YOU ASK?

, well if your reading this your NEW to doing "Hardwire" decoder installs, so don't take any chances do it right:winki: , leave the "tricks" to the pro's:toug::119: .

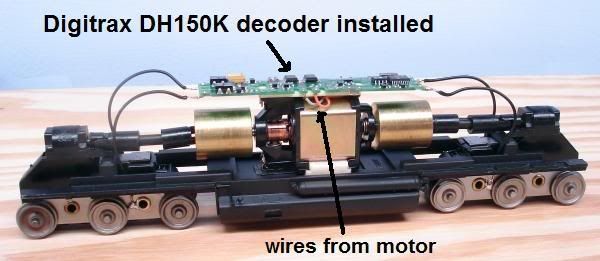

NOW that we have the wheel pick up jumper wires installed, we will take and bare the ends of the wires on the sound decoder that we are going to use:winki: . the wires on decoders/sound decoders are color coded, the codes for each wire color coming out of the decoder are:

RED- WHEEL CURRENT PICK UP #1

BLACK- WHEEL CURRENT PICK UP #2

ORANGE- RIGHT MOTOR WIRE

GRAY- LEFT MOTOR WIRE

WHITE- HEADLIGHT

YELLOW- TAIL LIGHT(no tail light on this install)

BLUE- THE COMMON WIRE FOR

BOTH, THE HEADLIGHT AND TAILLIGHT

:winki: .

GREEN- FUNCTION F1(we wont use this)

PURPLE- a function wire we wont use either for this install.

2 BROWN WIRES- speaker/s

OK, going by the wire codes i have provided, and the pic i posted below this, solder it all up, don't forget to use your NEW DCC compatible light, and use heat shrink wire wrap to cover ALL the bare wires when your done.

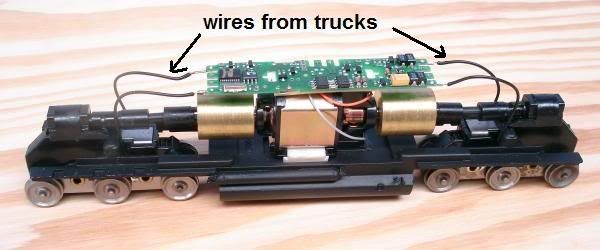

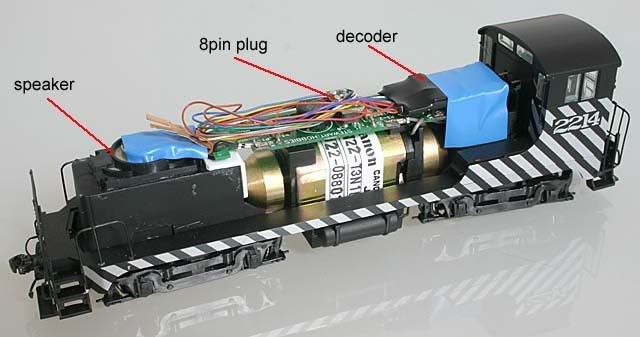

OK, now that we have it all wired up, re-install your light, neatly wrap up the extra wiring and tape it in place so it doesn't move around. (see pic below) at this time i take a drop of hot glue and put it on the bottom of the

speaker baffle/case(NOT ON THE SPEAKER ITS SELF!:eeki: ), then place it on the styrene shelf...

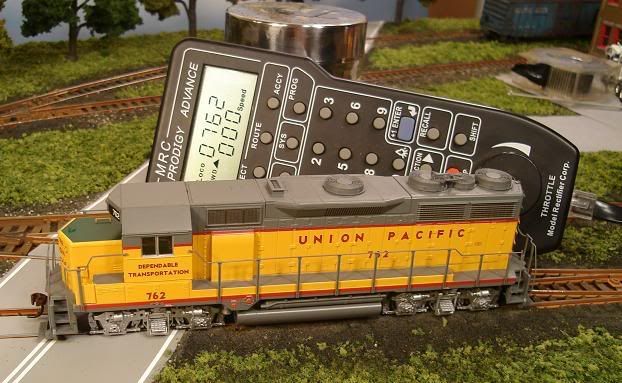

NOW place the engine shell back on its frame and...

WE ARE DONE!

:thumb::thumb::thumb:

SEE, not hard at all:thumb::mrgreen:

Put the engine on your track, program it, and ENJOY IT!

I hope this helps some of you out:winki::smilie: .

, THANK YOU DAN!!!

-Deano ** without further adieu, heres Dans tutorial;