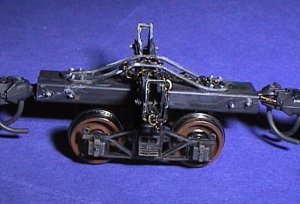

These are all brass, except for the NBWs and the axels (P2K metal wheelsets). I used brass as much as possible for weight. Shamus gave me hte old brass trucks a long time ago. Too bad these old brass trucks are no longer available. If I were to do another set, I would use some kadee trucks which are just as weighty.

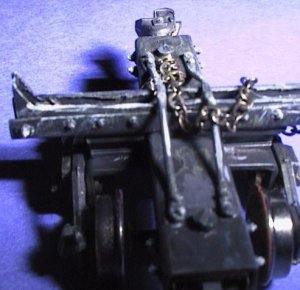

Also I used no solder. Partly, because I didn't feel like soldering, and partly because a lot of you don't like to solder, and I thought I would see if I couold work effectively with brass without solder. I used gel CA.

Also I used no solder. Partly, because I didn't feel like soldering, and partly because a lot of you don't like to solder, and I thought I would see if I couold work effectively with brass without solder. I used gel CA.