The power district simply allows you to run a lot more locos on your layout. It has everything to do with the capacity of your command station/booster, which is discussed under Laws of DCC on my website (Click on DCC from the index and then Laws of DCC).

There are two limitations to your command station/booster. The first is the number of "slots" or locos that your command station can handle at one time. For example the Digitrax Zephyr can handle 11 locos, the Empire Builder 22, the Chief 122, the Atlas Commander 7, etc.

The second is the power available from your command station or booster. Assume each locomotive draws 0.5 amps and your command station/booster is rated at 5 amps. The math tells us that you can run a maximum of 10 locos at one time on your layout (0.5 amps x 10 locos = 5 amps). If you put an 11th loco on your layout, you will start to blow a fuse. At least in theory.

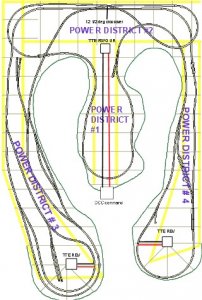

One way to overcome this limit in power (amps) is to add a booster. A booster is simply a command station/booster which is configured to simply act as a booster. And then we isolate the track controlled by this booster from the track controlled by the first command station/booster. When we isolate the track controlled by the command station/booster, we have a power district. When we isolate the track controlled by the booster, we have another power district - a total of two power districts on the layout.

Assume your booster is 5 amps and your locos draw 0.5 amp each. Applying the same math, we can run 10 locos on the second power district. So, on our layout, we can run a total of 20 locos at once - 10 on the power district controlled by the command station/ booster and 10 on the power district controlled by the booster.

However, we have to make sure that we don't have too many locos in one of the power districts as we will now exceed the current draw (the amps) in the power district. For example, assume you have 10 locos in Power District #1, each loco draws 0.5 amps and the capacity of the command station/booster is 5 amps.

We now run an 11th loco into Power District #1. This 11th loco draws 0.5 amps so we now are pulling a total of 5.5 amps out of the command station/booster (11 locos x 0.5 amps = 5.5 amps). We have now exceeded the capacity of the command station/booster and we will start to blow some fuses.

Of course, there' another question to answer and that is how many slots do you have on your command station. Obviously, if you have an Atlas Commander, which has 7 slots, or a Digitrax Zephyr, which has 11 slots, you won't be able to run 20 locos on your layout. But that's another story.

And what is the likelihood you will ever run more than 10 locos at once that draw 0.5 amps each on your layout. If you're running Athearns, they draw a lot of current (but certainly less than 0.5 amps), and if you're running Atlas or Kato's, they don't draw anything near 0.5 amps each.

So, you have to take a look at a number of things before you decide to create power districts and invest in boosters. It all depends on how many locos you're going to run on your layout at once and how much amperage each one of those locos will draw.