I'm building the Cylon Basestar from stevespaper.

Because it doesn't contains too much parts, so it's easy to build.

What a fatal mistake. wall1

Right is: Not that much parts.

Not right is: Easy to build (really weird folding and fuzzy instructions)

But I paid for the printing, so I'll build it. :mrgreen:

Printed on DIN-A3 (297mm x 420mm) Sheets with 160g/qm

The first part is the central core.

It's a little tricky to build because of the mechanism in it.

You can turn it 180 degrees, so that you can set the model to space or atmospheric configuration.

Assembled central core

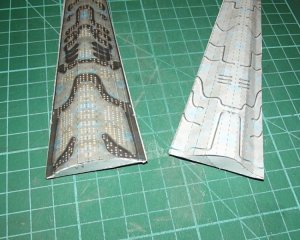

Parts for the wishbone center (lower half)

Parts for the wishbone center (upper half)

Assembled upper half of the wishbone center

Hard piece of work because it's hard to see how to fold the parts.

Because it doesn't contains too much parts, so it's easy to build.

What a fatal mistake. wall1

Right is: Not that much parts.

Not right is: Easy to build (really weird folding and fuzzy instructions)

But I paid for the printing, so I'll build it. :mrgreen:

Printed on DIN-A3 (297mm x 420mm) Sheets with 160g/qm

The first part is the central core.

It's a little tricky to build because of the mechanism in it.

You can turn it 180 degrees, so that you can set the model to space or atmospheric configuration.

Assembled central core

Parts for the wishbone center (lower half)

Parts for the wishbone center (upper half)

Assembled upper half of the wishbone center

Hard piece of work because it's hard to see how to fold the parts.