Howdy all,

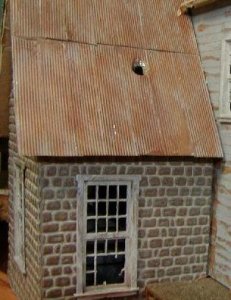

I'm putting a corrugated metal roof on my freight loading dock and I am using aluminum foil. I'm looking for some input on weathering the roof.

I'm using aluminum foil partially because I like the thickness of it over the commercially available corrugated roof products... but mainly because I'm cheap and I like doing stuff on my own. I've thought of using some sort of photo-etching chemical to craze the finish and eat parts of the foil away. Does anyone have any knowledge/experience with this idea/technique?

Also, anyone have tips on doing some rust weathering on it? I tried just drybrushing some rust color acrylic paint over it with mixed results. I'm thinking of painting it solid gray and then drybrushing again. The brightness of the foil under the rust color just didn't look right... galvanized metal isn't that shiny afterall.

I'm also looking for any other input on corrugated metal roofs ya'll may have. Thanks beforehand for your input and thoughts.

Joel

I'm putting a corrugated metal roof on my freight loading dock and I am using aluminum foil. I'm looking for some input on weathering the roof.

I'm using aluminum foil partially because I like the thickness of it over the commercially available corrugated roof products... but mainly because I'm cheap and I like doing stuff on my own. I've thought of using some sort of photo-etching chemical to craze the finish and eat parts of the foil away. Does anyone have any knowledge/experience with this idea/technique?

Also, anyone have tips on doing some rust weathering on it? I tried just drybrushing some rust color acrylic paint over it with mixed results. I'm thinking of painting it solid gray and then drybrushing again. The brightness of the foil under the rust color just didn't look right... galvanized metal isn't that shiny afterall.

I'm also looking for any other input on corrugated metal roofs ya'll may have. Thanks beforehand for your input and thoughts.

Joel