I'm still in my design stage for my n scale layout

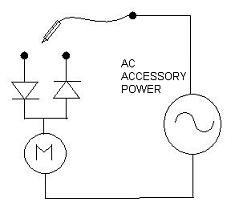

. I will be using the twin-coil switch machines mounted under the track bed, for the mainline and sidings. And manual hand thrown switches for the yard.

. I will be using the twin-coil switch machines mounted under the track bed, for the mainline and sidings. And manual hand thrown switches for the yard.

My question is on my control panel . What should or can i use? Should i use push buttons or SPTD switches to operate my switches from my control panel? Or is that a personel preference also.

Thank you all for your help again

,

,

Cliff

My question is on my control panel . What should or can i use? Should i use push buttons or SPTD switches to operate my switches from my control panel? Or is that a personel preference also.

Thank you all for your help again

Cliff