Clickable Trackplan

- Thread starter shamus

- Start date

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Fantastic

Hello paul,

your On30 is looking just fine, ....... mighty fine in deed!

Love the picture from 'in the tunnel'. It is something that you would normally only see in a prototype shot. Well done!

BTW Paul, what did you use for all the belts in your sawmill? They look pretty good.

Keep it up Paul,

Drew

Hello paul,

your On30 is looking just fine, ....... mighty fine in deed!

Love the picture from 'in the tunnel'. It is something that you would normally only see in a prototype shot. Well done!

BTW Paul, what did you use for all the belts in your sawmill? They look pretty good.

Keep it up Paul,

Drew

Nice webpage stuff Shamus!

Are you writing your own code or using templates? I've just started learning to write code and am curious as to what software and tecniques you are using.

Man... This guy can do EVERYTHING!!

Are you writing your own code or using templates? I've just started learning to write code and am curious as to what software and tecniques you are using.

Man... This guy can do EVERYTHING!!

Thanks kind people, for those of you wishing to try this, you will need a program similar in features to Paintshop Pro7 to upload a photograph. Once the photo is on screen go to "File/Export/Image mapper" from then on its just a question of what area's you wish to make into photographs. Very difficult to try and explain a new program that I have only been playing with for a short time.

Here's a screen capture of it.

What it does is once all the clickable areas that you require are finished, is to save your photo as a "jmd" file along with an htm file of the same photo. Once this is uploaded to your website (Or Hosting site) it allows you to bring in the photo, move the mouse over your clickable areas and click on an area of the photo enlarged.

Cheers friends

Shamus

Here's a screen capture of it.

What it does is once all the clickable areas that you require are finished, is to save your photo as a "jmd" file along with an htm file of the same photo. Once this is uploaded to your website (Or Hosting site) it allows you to bring in the photo, move the mouse over your clickable areas and click on an area of the photo enlarged.

Cheers friends

Shamus

Hmmm.... VERY slick!! I have Paintshop Pro 6 which I don't think has this feature...I will have to try to get version 7!

Shamus..are you writing all the code for your webpages from scratch or are you using some kind of templates or program??

Shamus..are you writing all the code for your webpages from scratch or are you using some kind of templates or program??

Hi Art,

If you look at the PSPyou have and go to "File" bring the mouse down to "Export", it should be there the "Image Mapper".

As for my website, I use frontpage, and write everything for it. although it makes some htm code, you still have to do all the hyperlinking (And Thinking) otherwise it won't work. LOL

Cheers

Shamus

If you look at the PSPyou have and go to "File" bring the mouse down to "Export", it should be there the "Image Mapper".

As for my website, I use frontpage, and write everything for it. although it makes some htm code, you still have to do all the hyperlinking (And Thinking) otherwise it won't work. LOL

Cheers

Shamus

Hi Shamus...Nope Paint Shop Pro version 6 does not have the image mapper feature.

It's not under file> export or listed anywhere in the help index. PSP 6 is a few years old so it doesn't surprise me that it's not there.

I can get PSP 7.......and plan on doing that.

I've heard Front Page is a great html program..and I think it be free or cheap Gonna have to check that out too.

Gonna have to check that out too.

I've just been using notepad, and an online tutorial, to write my code. Lots to learn....not enough time to do it quickly lol

It's not under file> export or listed anywhere in the help index. PSP 6 is a few years old so it doesn't surprise me that it's not there.

I can get PSP 7.......and plan on doing that.

I've heard Front Page is a great html program..and I think it be free or cheap

I've just been using notepad, and an online tutorial, to write my code. Lots to learn....not enough time to do it quickly lol

Shamus, It works great.You have a great style,an awesome style.I just love that old time sawmill.

Now, as a note.Having worked on a few oldtime mills in my day(wifes uncle owns one)A few notes for you.

First off, them guys on the off chute are doing way too much standing around

Second off there would be at least 2 and more likely 3 drays on the end of that line.Either cart style or sled style.There would also be a stack of slab wood and way more bark around the offchute.1 dray is for slabs, the other 2 are for differant dimensions of lumber. 2x4's on 1 and larger seperated by slab sheets on the other.

Your operation looks great but its way too clean for that many employees.This is a sawmill afterall.Think OSHA and make em cringe

Wouldnt want you to find yourself with nothing to do now would we

Now, as a note.Having worked on a few oldtime mills in my day(wifes uncle owns one)A few notes for you.

First off, them guys on the off chute are doing way too much standing around

Second off there would be at least 2 and more likely 3 drays on the end of that line.Either cart style or sled style.There would also be a stack of slab wood and way more bark around the offchute.1 dray is for slabs, the other 2 are for differant dimensions of lumber. 2x4's on 1 and larger seperated by slab sheets on the other.

Your operation looks great but its way too clean for that many employees.This is a sawmill afterall.Think OSHA and make em cringe

Wouldnt want you to find yourself with nothing to do now would we

Thanks I think, could you explain better with a drawing of what these drays and off shutes are please. never seen on here in the UKOriginally posted by Tileguy

Shamus, It works great.You have a great style,an awesome style.I just love that old time sawmill.

Now, as a note.Having worked on a few oldtime mills in my day(wifes uncle owns one)A few notes for you.

First off, them guys on the off chute are doing way too much standing around

Second off there would be at least 2 and more likely 3 drays on the end of that line.Either cart style or sled style.There would also be a stack of slab wood and way more bark around the offchute.1 dray is for slabs, the other 2 are for differant dimensions of lumber. 2x4's on 1 and larger seperated by slab sheets on the other.

Your operation looks great but its way too clean for that many employees.This is a sawmill afterall.Think OSHA and make em cringe

Wouldnt want you to find yourself with nothing to do now would we

shamus

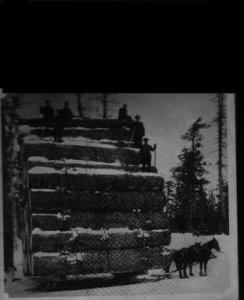

Shamus, please dont get me wrong,it looks great.But with your eye for detail,I just thought perhaps you werent aware of a couple of items.Off chute is basically your roller coming down from the mill.the log runs through the mill on the carriage(some are 2 head block but most are 3 head blocks)when the log is run through it is eyed by the sawyer and squared up.Starting on one side of the log,the first piece is cut(this we call a slab,it has the bark etc on it).The log is then turned a full 180 degrees so the flat of the log(where the slab was removed) rests against the Headblocks.It is then slabbed again.the log is then turned again and laid on the flat in the carriage and slabbed a third time.This gives you a log with 3 square sides.The log is then run through the mill at a set width of board.2" for a 2x4 1" for a 1x4 etc.Now the log may be cut into lets say 2x8's through 2/3 to 3/4" of it.it may then be turned,slabbed on the last side and then finished out in 1" Material.It all depends on the log.every Sawyer does things a little differant,but the idea is to get as much usable lumber out of the piece of wood as possibleAs the pieces are cut from the board they come down the chute(ussually made of rollers) the Tenders will then remove the roughsawn material seperating the slab from the dimension lumber and stack the dimension lumber into sizes on drays and the slabs onto another dray.. These drays can then be moved to the planing shed/slab pile,Planed on a 4 side planer,restacked on drays and run out to the kiln or in the case of old time mills,Curing shed and strip piled.In the case of the slabs,they are generally bundled and sold as firewood. A dray is a term used for any conveyance to haul logs,lumber etc from one place to another.Some are made of cants(squared up timbers) sliced off on one end at an angle to act as ski's(they are also called log boats.they generally have 4-6 upright timbers and several timbers for a platform across the cants.They were filled and then drug by a horse team or old tractor.Wagons were modified also to act as drays.Generally they were used only in mill service to move finished lumber and slab wood to designated area's

We use old truck rear ends with a welded pipe framework for our drays.Most oldtimers used wooden framing and old wagon wheels,Heavy duty ones and horses to drag them.If you are modelling the late twenties and your mill is prosperous, you may have an old tractor around with log forks for moving the drays and loading the skidway(this holds the logs that are to be sawed and generally has 3 rails or logs on uprights that meet up to the height of the carriage on the mill.it also has stops to keep the logs from rolling onto the mill).One of the nicest skidways ive run across was made from old rail. 3 rails in the 60-70 lb class were spiked down to ties dug into the earth and cut off at the proper height .the skidway was about 40 feet long and ive seen it stacked with 5-6 cord of red oak to be sawn.

Dangerous is the word for milling trees.The metal roof on the mill shed at the wifes uncle's has many holes in it from pieces of metal or from blade teeth being shot through it.A good reason not to bring trees from residential yards in to be sawed up.

I hope you find something useful to you here,i most certainly was not criticizing your work,i only hope mine is as good one day

Now, after all that, i have a question for you.Do you think i can make this work as a logo for a private road name ?and any thought on design would be appreciated

We use old truck rear ends with a welded pipe framework for our drays.Most oldtimers used wooden framing and old wagon wheels,Heavy duty ones and horses to drag them.If you are modelling the late twenties and your mill is prosperous, you may have an old tractor around with log forks for moving the drays and loading the skidway(this holds the logs that are to be sawed and generally has 3 rails or logs on uprights that meet up to the height of the carriage on the mill.it also has stops to keep the logs from rolling onto the mill).One of the nicest skidways ive run across was made from old rail. 3 rails in the 60-70 lb class were spiked down to ties dug into the earth and cut off at the proper height .the skidway was about 40 feet long and ive seen it stacked with 5-6 cord of red oak to be sawn.

Dangerous is the word for milling trees.The metal roof on the mill shed at the wifes uncle's has many holes in it from pieces of metal or from blade teeth being shot through it.A good reason not to bring trees from residential yards in to be sawed up.

I hope you find something useful to you here,i most certainly was not criticizing your work,i only hope mine is as good one day

Now, after all that, i have a question for you.Do you think i can make this work as a logo for a private road name ?and any thought on design would be appreciated

Attachments

Hey, it coulda been worse, you mighta had to scratchbuild it in N scale

You know, i never asked this, do you have any animations on your layout?a couple sawyers with a 2 man saw cutting a tree, or a welding flash unit or anything as such?Special effects kinda stuff.

You know, i never asked this, do you have any animations on your layout?a couple sawyers with a 2 man saw cutting a tree, or a welding flash unit or anything as such?Special effects kinda stuff.

Hmmmm....my bet is that tileguy has inspired and got Shamus thinking and it won't be long before we see new scratchbuilt lumber equipment on Shamus' layout...uhhuh I bet  lol

lol