I recently purchased one of these anf find that when I cut 1/16" by 1/16" stock the blade tends to wander,thus defeating the hole point of buying the product. I installed a new blade and made sure that the screws were tight so that's not the problem(s). I Email NWSL and after three days still no response. Did anyone else have a similar experience and get any solutions?????

chopper III

- Thread starter belg

- Start date

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

The Chopper uses a single edge razor blade, which, by its nature, is a bit flexible, and will tend to drift while cutting.

I have found that in order to get the most accurate cut, I have to apply a steady, slow pressure. this will help the blade cut straight through.

NWSL has the fix for this, it's called the precision sander. Yes, that sounds like a smart ***ed remark, but if absolute accuracy is needed, this is the best way. For most applications I have been very happy with the Chopper. I have photos posted, some time back, of a pair of C&O cabooses that I scratch built. The Chopper was used extensively for the construction.

While nothing is perfect, the Chopper is close enough for most projects.

Pete

I have found that in order to get the most accurate cut, I have to apply a steady, slow pressure. this will help the blade cut straight through.

NWSL has the fix for this, it's called the precision sander. Yes, that sounds like a smart ***ed remark, but if absolute accuracy is needed, this is the best way. For most applications I have been very happy with the Chopper. I have photos posted, some time back, of a pair of C&O cabooses that I scratch built. The Chopper was used extensively for the construction.

While nothing is perfect, the Chopper is close enough for most projects.

Pete

Pete I don't now if you work(ed) for nwsl but thier response was almost a dead on copy of what you said. Now that being said I'm not all that happy with this response,how can you make a tool that does not cut straight just to sell you another one to fix wath the first one didn't do right?????????

I hope that the rest of their material is judged to a much finer standard,since they make tiny gears and like.

I hope that the rest of their material is judged to a much finer standard,since they make tiny gears and like.

I am newer to scratch building than most. So far I have worked on two projects. But in those two projects I used the Chopper II about a couple of hundred times - lots of repetitive cutting. In fact, I would have had great difficulty with the projects and they wouldn't have looked as good, if I hadn't used the chopper. I ask my son for it for Xmas of 2002. One of the better gifts I have received over the years from folks.

Kind of like the self sealing mat. I can't imagine life without one.

Kind of like the self sealing mat. I can't imagine life without one.

Pete I don't now if you work(ed) for nwsl but thier response was almost a dead on copy of what you said

In the first, I was being only slightly sarcastic.I hope that the rest of their material is judged to a much finer standard,since they make tiny gears and like.

As for the gears, My HOn3 2-4-4-2, has NWSL gear boxes, and has run at module shows for the last 16 years!! The only gearbox failure I've had was my fault. I didn't get the alignment right, and after about three years operation, the worm gear disintegrated.

If I push it, my Unimat will make bad parts, Years ago someone once told me, "let the tool do the work". They will, if you let them. Part of working with tools is learning how to work with tools.

Oh,, I do not have a precision sander, really!

Pete

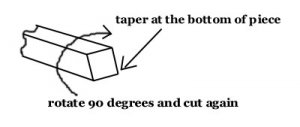

As with ant type of knife cutter there is some taper in the cut. Just cut the 1/16 stock with a brand new x-acto blade and examine the cut. You will see the taper. When I need a square end I either recut about .010 off by eye or sand with a square, like the NWSL sander.

Oh...... and even after reading the first post, I thought... He's in the wrong forum.... this is model railways, not model helicopters with bung blades..............

A chopper? What's a chopper??

A chopper? What's a chopper??

Hey Woodie I not sure if you"re being sarcastic about not knowing what a chopper is or just don't know, so assuming the latter, it is a tool to cut repeated "similar" pieces it has a stop a handle to which you mount a single edge razor.Needless to say but I will I'm not happy with the results or the answer to my problem that I got from the company,which was to buy another one of thier tools to fix the inadequatecies of the first product.

Gee, now they're acting like a software company. They'll get it almost right around Chopper XVII and add the features you want on the "Super Chopper", at twice the price of course....Originally posted by belg

...I'm not happy with the results or the answer to my problem that I got from the company,which was to buy another one of thier tools to fix the inadequatecies of the first product.

Don

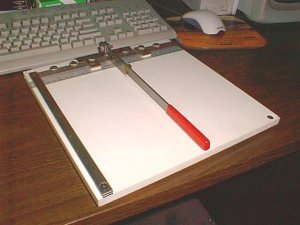

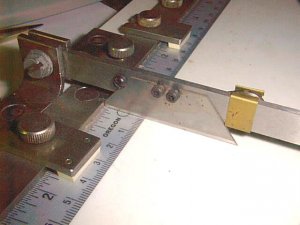

I built my own chopper using Corian for a base and Starrett steel stock for the handle and guides. I chose to use the utility knife style blades instead of the single edge razor blades because they are more rigid. On thicker material, the tapered end is always a problem. This is not NWSL's fault. When you cut through a piece of material, you have to make way for the thickness of the blade. I used a self adhesive scale from Micro Mark. On thicker material, I find it is better NOT to use a physical stop as it forces the piece on the opposite side to move. By using the scale, the material on both sides of the blade move equally and tend to give you a straighter cut. Another thing you can do if you are using a stop, is to cut the material once, rotate the part 90 degrees and cut it again.

Attachments

Kool Tool, Blake! Looks kinda like those office paper cutters (hmm - wonder how they'd work?)

Went out to NWSL's website (http://www.nwsl.com), where they have a PDF file describing the Chopper II. Doesn't say anything about the problem, although it does indicate a 1/4" maximum cutting depth. It repeatedly trumpets the accuracy, precision and repeatability of the thing, but there is one curious phrase:

"...cuts any angle (whether it maintains the angle you want or not) complexity." What the hell does that mean?

Anyway, only thing I can think of is to find more rigid razor blades, if there is such a thing.

Went out to NWSL's website (http://www.nwsl.com), where they have a PDF file describing the Chopper II. Doesn't say anything about the problem, although it does indicate a 1/4" maximum cutting depth. It repeatedly trumpets the accuracy, precision and repeatability of the thing, but there is one curious phrase:

"...cuts any angle (whether it maintains the angle you want or not) complexity." What the hell does that mean?

Anyway, only thing I can think of is to find more rigid razor blades, if there is such a thing.

Maybe what we want is a blade that has the edge tapered on only one side

| |

\ |

\|

The piece you are cutting to length is on the right side of this blade.

wr

| |

\ |

\|

The piece you are cutting to length is on the right side of this blade.

wr

aaahhhh..... So that's a Chopper... (which I assume is a brand name??). Sorta like a guillotine thing.

Can you use it to cut out window holes in sytrene sheet? I'm having lots of trouble doing that, getting them accurate, square, and consistent, with good square corners.

Can you use it to cut out window holes in sytrene sheet? I'm having lots of trouble doing that, getting them accurate, square, and consistent, with good square corners.

Hey Woodie, been awhile. I don't think the Chopper (that's a brand name, BTW) does windoows.

What you want is some kind of punch that either does squares or square corners. I know I've seen/heard of them somewhere, probably someone less senile can fill us in!

What you want is some kind of punch that either does squares or square corners. I know I've seen/heard of them somewhere, probably someone less senile can fill us in!

Belg, I have both the original Chopper and the Chopper II. I still prefer the original because it's easier, I think, to visually line up measured/marked stripwood under the blade.

Now as to getting square cuts (more or less ), what I do - especially with thicker stock - is cut the piece only part of the way through. Then I rotate it and cut it again. I repeat this twice more, for a total of 4 partial cuts, 1 per side. Sometimes the wood is cut all the way through before the 4th cut, but that's OK, too, because I always run the ends across the "True-Sander."

), what I do - especially with thicker stock - is cut the piece only part of the way through. Then I rotate it and cut it again. I repeat this twice more, for a total of 4 partial cuts, 1 per side. Sometimes the wood is cut all the way through before the 4th cut, but that's OK, too, because I always run the ends across the "True-Sander."

Personally, I don't think you can beat the Chopper or the Sander if you're trying to do precision work and have a number repetitive cuts to make and square up.

Now as to getting square cuts (more or less

Personally, I don't think you can beat the Chopper or the Sander if you're trying to do precision work and have a number repetitive cuts to make and square up.

Woodie:

Chopper is made by NorthWest Short Line.

I don't think it would do windows, because it cuts right up to the fence, although someone with more guts (or less blood) than me might be able to cut down the razor blade and mount it out a bit.

B]Kids, don't try this at home![/B]

So far, I'm happy with Chopper II, except for the nuts that hold the angle bits, which have stripped. NWSL changed then from being cast around a brass nut to pure plastic.

Chopper is made by NorthWest Short Line.

I don't think it would do windows, because it cuts right up to the fence, although someone with more guts (or less blood) than me might be able to cut down the razor blade and mount it out a bit.

B]Kids, don't try this at home![/B]

So far, I'm happy with Chopper II, except for the nuts that hold the angle bits, which have stripped. NWSL changed then from being cast around a brass nut to pure plastic.