Capacitor Discharge unit

- Thread starter Xaniel

- Start date

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Okey dokey, that's what I thought. The "motor" is simply a solenoid. Again, out of curiosity, does anyone have an idea of the timing, like what is the minimum time needed to get a positive switch, and what is the maximum time before you start smelling smoke?

Also, how much current are we talking here?

Also, how much current are we talking here?

Another question, is there a need to improve this? I'm just thinking that there has to be a more consistant and predictable way to do this and it needn't be high tech either. I guess I'll never stop returning to my roots. I know I didn't start this thread, but something about this is intriguing and I wouldn't have known a thing about it if it wasn't started.

I know I didn't start this thread, but something about this is intriguing and I wouldn't have known a thing about it if it wasn't started.

Edit: Thanks for posting the pictures Ron. You were posting them the same time I was composing this.

Don

Another question, is there a need to improve this? I'm just thinking that there has to be a more consistant and predictable way to do this and it needn't be high tech either. I guess I'll never stop returning to my roots.

I know I didn't start this thread, but something about this is intriguing and I wouldn't have known a thing about it if it wasn't started.

I know I didn't start this thread, but something about this is intriguing and I wouldn't have known a thing about it if it wasn't started.Edit: Thanks for posting the pictures Ron. You were posting them the same time I was composing this.

Don

Don, I'll try to give you some useful answers...

At first the capacitor is charged - compare this to a water tank which is filled up. When you press the button, a circuit through the switch solenoid is closed and the capacitor is discharged, thereby actuating the turnout. (You are tipping the tank, so to speak, so all its content is spilled in one big splash!)

Now the current (in Amperes) depends on the voltage of the capacitor (as Shamus said, 24 V is fine) and the electrical resistance of the solenoids. In a setup like the one I built up, the discharge of the capacitor gives a burst of current which lasts for maximum some tenths of a second. Since you are depressing the button only for an instant, there is no danger of burning out the switch machine(s). And as soon as you release the button, the capacitor is recharged again (which is done in a few seconds).

)

)

I found that the size shown above (4700 Microfarad) is more than ample for the actuation of up to five turnouts together. For one or two turnouts at a time 2200 Microfarad should suffice.

In the charging circuit you could include an additional resistor to keep loading current down. This gives some additional security, but so far I had no problems without.

Important: Use a push button, never a switch! Otherwise you'll have an ongoing current through the solenoids - and in this case they could burn out rapidly. In this case you would smell some smoke!

And BTW: Take care when wiring an electrolytic capacitor: When you reverse the polarity, it explodes. It's not so much the danger of flying debris - but the thing STINKS, oh Boy! (I know

)

)

Ron

PS: Wow, this answer became somewhat king-sized, but I hope it helped a bit...

Time isn't a problem. The crucial point is the size of the capacitor....what is the minimum time needed to get a positive switch?

At first the capacitor is charged - compare this to a water tank which is filled up. When you press the button, a circuit through the switch solenoid is closed and the capacitor is discharged, thereby actuating the turnout. (You are tipping the tank, so to speak, so all its content is spilled in one big splash!)

Now the current (in Amperes) depends on the voltage of the capacitor (as Shamus said, 24 V is fine) and the electrical resistance of the solenoids. In a setup like the one I built up, the discharge of the capacitor gives a burst of current which lasts for maximum some tenths of a second. Since you are depressing the button only for an instant, there is no danger of burning out the switch machine(s). And as soon as you release the button, the capacitor is recharged again (which is done in a few seconds).

Capacitor size is important, too. If you take a giant capacitor, there is more electrical charge - and it could be too much, since the discharge current flows longer and this could build up some heat in the solenoids. So don't use an oversized capacitor, and there should be no smoke problems! (Compare again: You could clean your porch by gushing a bucket of water over the planks. You wouldn't gush the same porch with a railroad water tower, would you?...what is the maximum time before you start smelling smoke?

I found that the size shown above (4700 Microfarad) is more than ample for the actuation of up to five turnouts together. For one or two turnouts at a time 2200 Microfarad should suffice.

In the charging circuit you could include an additional resistor to keep loading current down. This gives some additional security, but so far I had no problems without.

Important: Use a push button, never a switch! Otherwise you'll have an ongoing current through the solenoids - and in this case they could burn out rapidly. In this case you would smell some smoke!

And BTW: Take care when wiring an electrolytic capacitor: When you reverse the polarity, it explodes. It's not so much the danger of flying debris - but the thing STINKS, oh Boy! (I know

Ron

PS: Wow, this answer became somewhat king-sized, but I hope it helped a bit...

Ron,

Thanks for the detailed reply. You gave me the prospective all from the CDU, but not from the load. For example, the load has DC resistance and that determines the current it will need at its rated voltage. There is also a finite time that the signal (voltage) must be present in order for the coil (point motor) to operate. That can be a few milliseconds to a few hundred milliseconds. And as you say, if you maintain the voltage too long, smoke, so there is a maximum time as well...

I am just curious if this can be solved using an electronic pluse of a given time duration and energy so that one would not have to be concerned about recharging a capacitor or keeping your finger on the button too long. I could do some experimenting, but all I have here is some Atlas and LL N scale switch machines.

Oh yeah, you can ask my wife about reverse polarity caps. We used to make small power supplies at our business, and she didn't put them in backwards too often, but it was obvious to all when she did.

Paul,

I am curious about this whole thing. Maybe I have too much time on my hands, but I can't do much else until we are settled in our new house.

Don

Thanks for the detailed reply. You gave me the prospective all from the CDU, but not from the load. For example, the load has DC resistance and that determines the current it will need at its rated voltage. There is also a finite time that the signal (voltage) must be present in order for the coil (point motor) to operate. That can be a few milliseconds to a few hundred milliseconds. And as you say, if you maintain the voltage too long, smoke, so there is a maximum time as well...

I am just curious if this can be solved using an electronic pluse of a given time duration and energy so that one would not have to be concerned about recharging a capacitor or keeping your finger on the button too long. I could do some experimenting, but all I have here is some Atlas and LL N scale switch machines.

Oh yeah, you can ask my wife about reverse polarity caps. We used to make small power supplies at our business, and she didn't put them in backwards too often, but it was obvious to all when she did.

Paul,

I am curious about this whole thing. Maybe I have too much time on my hands, but I can't do much else until we are settled in our new house.

Don

I use both stall motor and solenoid type switch machines, I run both from the same power supply. I do not use any capacitors. I simply use a 12 volt transformer rectified to DC, yielding about 10 1/2 volts. When I first built a diode matrix for one of the staging yard throats, my original power supply couldn't throw multiple turnouts. I tried increasing the voltage but that really didn't help much. When I measured the resistance of the coil, it was practically nothing. This was on a Rix machine, others are probably similar. So, current draw was high. My present transformer is 12 volt, 8 amp. I have a 6 amp fuse on the output. I can now reliably throw five turnouts at once, the most I need to. And I can throw five more immedietely. Note I do not use push switches, they get welded in short order. I use the stud and probe method, like Shamus. Just touch the probe to the stud and remove. Now, if you were to let the probe stay in contact with the stud, the coil will heat rapidly. Melting of the plastic housing takes between five and ten seconds. So a push button that welds itself will destroy the machine if you don't get power off pretty quickly. This I suppose is the advantage of a cap discharge.

I've always understood that the CDU would only let a trickle of current by after it discharges. I know that we've had pushbuttons jam on and the CDU never gets recharged, but I don't recall any problem with the switch machines going.

Originally posted by ezdays

Ron,

I am just curious if this can be solved using an electronic pluse of a given time duration and energy so that one would not have to be concerned about recharging a capacitor or keeping your finger on the button too long. I could do some experimenting, but all I have here is some Atlas and LL N scale switch machines.

Oh yeah, you can ask my wife about reverse polarity caps. We used to make small power supplies at our business, and she didn't put them in backwards too often, but it was obvious to all when she did.

This link has a lot of MRR circuits, several CDU:

http://home.cogeco.ca/~rpaisley4/CircuitIndex.html#index

The coils can't burn out once the capacitor is discharged which happens quickly, so holding the switch on won't hurt anything. Some of these circuits may use a resistor to charge the cap back up when the switch is released, but enough resistance will protect the coils (and lengthen the recharge time). A neat way shown in some of these circuits is a transistor that limits the constant current when the switch is held closed, but which allows higher current when the switch is opened again to recharge the cap quickly.

As for reversed capacitors - a buddy of mine in his practical joking younger years would occasionally sneak into work early and solder a little 16 V electrolytic cap across the AC power of the secretary's electric typewriter. When she came in and turned it on the BANG

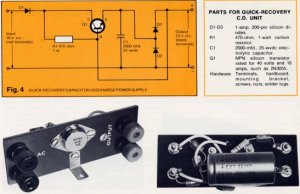

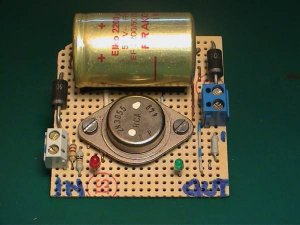

Xaniel, I posted a circuit diagram if a CDU which I use on my layout. It operates 4 switches simultaenously and can operate more. Mine is powered from an 18 volt DC supply but can also be AC without modification.

A problem using ac through a pushbutton is that eventually, because of the high surge current the pushbutton can stick in the "Pressed" position resulting in the machines frying in 2 to 3 seconds! .

Solution is to use a transistorised Capacitor Discharge unit. This is a simple device which supplies high current to the machines for a fraction of a second, then the transistor limits the power to a level that cannot possibly fry the machine (Even if the push button remains pressed indefinately. You will also get that beloved "snick" you expected to hear .

Here is a circuit you can build yourself for just such a Capacitor Discharge Unit. Have fun (and peace of mind).

Errol

A problem using ac through a pushbutton is that eventually, because of the high surge current the pushbutton can stick in the "Pressed" position resulting in the machines frying in 2 to 3 seconds! .

Solution is to use a transistorised Capacitor Discharge unit. This is a simple device which supplies high current to the machines for a fraction of a second, then the transistor limits the power to a level that cannot possibly fry the machine (Even if the push button remains pressed indefinately. You will also get that beloved "snick" you expected to hear .

Here is a circuit you can build yourself for just such a Capacitor Discharge Unit. Have fun (and peace of mind).

Errol

Attachments

Oh yeah, you can ask my wife about reverse polarity caps. We used to make small power supplies at our business, and she didn't put them in backwards too often, but it was obvious to all when she did.

i worked for the government buses and our fav trick with reversed caps was to put one across the starter motor reversed when the motor mech apprentices had installed a new motor

lotsa smoke,big bang

and all the tradesmen running across the floor going `what have you done.the boss is gunna kill us!!!'

and for the sparkies out there

mega the bosses chair

lol now thats fun

i worked for the government buses and our fav trick with reversed caps was to put one across the starter motor reversed when the motor mech apprentices had installed a new motor

lotsa smoke,big bang

and all the tradesmen running across the floor going `what have you done.the boss is gunna kill us!!!'

and for the sparkies out there

mega the bosses chair

lol now thats fun