Hi t, It looks great. I take it you are building on your workbench and then laying? In regard to the tie templates, I used to use them too, I stopped after my first 5 or 6 turnouts when my confidence level went up and I realized there was no reason to confine myself to #6, or 8 or 4 for that matter. There certainly is no relation to the prototype in those sizes. Trackplans call for them because they are commercially available.

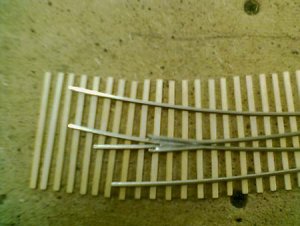

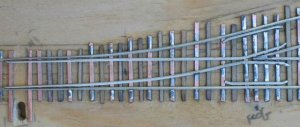

Now, I just layout the track centerlines, glue down the homabed (or cork, but homabed is better for spiking) on the centerlines then its time to glue ties to the homabed. I cut ties form commercially available switch ties. I cut them in 1' increments, 9 1/2, 10 1/2, so on. I built a jig to space the ties how I want them. Here is how I determine how many of each tie length to use, I developed this for curved turnouts. I use flextrack pinned down for one of the routes to mark where the tie ends will be, then do the same for the other route. Beyond the throwbar I usualy use 2 or 3 standard ties, then go to 9 1/2" ones. I simply see how far from the points the 9 1/2' tie matches the drawn lines, and put that many 9 1/2' ties in the jig, then do the same up to the full length switch ties, beyond which regular ties are used for each route. When all ties are in the jig, I use a thin strip of masking tape to move the strip into place on the homabed. Oh, before I forget, drill a hole under where the throwbar will be if you are using under table machine to throw the turnout before gluing the ties down. Once glued down, and sanded level, I paint the ties and homabed a suitable tie color. This seals the homabed to protect it from the water used in ballasting. There is presently another thread on coloring ties, and everybody else stains their ties. I used to also, but have decided to defy conventional wisdom, I feel it is easily possible to obtain the effects you want with paint. In addition to the paint sealing the homasote, which is important (and the ties adhere to the homabed with white glue very well prior to painting) I never liked having to seperate and turn ties after a stain bath. To each their own.

Next is ballasting. When this is dry and cleaned off tie tops, it is time to lay rail. No need to go into this, as you have done quite well! As long as the turnout in question is accesable on the layout, I prefer to build in place. Actually, I have never built one on my workbench.

I hope some part of this has been helpful.