I assume this post should go here, because our Valley N Trak club is scratching and bashing a number of structures. The stuctures are for a static display of the Beacon Falls Rubber plant, located on the Naugatuck River in Beacon Falls, CT, circa 1915. Everything is "N" scale and since the assigned display case is slightly smaller than 2 x 4 foot, we had to take some liberties. We will scale down and relocate some buildings to squeeze everything in the diorama. We are working from historical pictures taken during the era and here is a picture I took of the progress to date. It shows the plant side of the river looking down the trolley line. The covered bridge and steel tressel bridges go to the railroad line on the opposite side of the Naugatuck River. The pictured structures are the work of one club member, I sure hope some of his creativity rubs off on me.

Beacon Falls project

- Thread starter Bill Pontin

- Start date

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

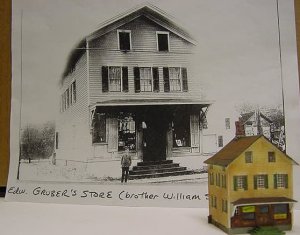

Here is a picture of a structure I just completed last night from scratch. It is of Edward Gruber's store located a little down the street from the rubber plant. I used styrene sheets to model the front and back walls. I then cast the two walls using the rubber mold material I purchased from Micro Mark. The sutters I made using duct foil tape that I embossed with the wheel of a Bic lighter. The windows are pieces of fiberglass window screening I cut and adhered to the inside of the wall. Tried cutting them to fit into the openings but that was too tedious. Used some Testors clear window maker cement to give the appearance of glass.

Attachments

Either using styrene componets I make, or modified parts from purchased kits, I make a mold using a two part rubber compound that cures in 4 hours. The ten minute curing plastic works fantastic, I am still playing with the thickness of the plastic. Trying different things with each pour to eliminate the flash but keep the thickness uniform. Both the rubber and plastic components I purchased and are available from Micro Mark. The best adhesive I found for the plastic is a product from Loctite called "Quicktite". It is a gell formula super glue that comes in a grey and blue bottle. It has a squeeze mechanism and an applicator tip that dispenses the glue precisely. Don't know how they did it, but I have had little or no clogging of the nozzle. (If you remember to keep it covered of course) If you are going to use it I recommend getting two bottles. There is not a large quantity in each bottle and it is very frustrating to run out in the middle of a project. I get mine from the "Orange Box" store for $2.00, see it other places but they are asking $2.65 to $3.00. One other thing I should mention about the dispenser bottle for those, like myself, that do not read all the instructions. To start the bottle you have to turn the cap down to puncture the seal.

Attachments

The pictured structures are the work of one club member, I sure hope some of his creativity rubs off on me.

Gruber's store seems to indicate that you got what you hoped for.

Nice!

Pete

Thanks Bill for all the info on molding. Someday i will be trying it, i always have wanted too. The pictures are excellent.

Wow.... making molds....very cool indeed!

A neophyte must ask tho, and really wants to know.... why make a mold?

Are you going to be making duplicates of the original model parts used to make the mold? Are the molds durable enough for multiple pours?

Or is it in case you make an OOPS!, you can just pour another part?

Or is it just because you can and its cool and fun??

A neophyte must ask tho, and really wants to know.... why make a mold?

Are you going to be making duplicates of the original model parts used to make the mold? Are the molds durable enough for multiple pours?

Or is it in case you make an OOPS!, you can just pour another part?

Or is it just because you can and its cool and fun??

Hi aartwmich,

Will try and answer a few of your questions about making the molds. They are fairly durable and I expect to get many parts from them. I am not looking to make duplicates of the same building but rather looking for a way to get more structure parts. Other than DPM and Grandt Line, there are not too many building components out there for us "N" scalers. Cutting window and door openings in textured styrene sheet stock is no small job. A good example is the "Gruber store" from above. Here I made two walls; one side and one back. Both side are identical castings and a casting of the back wall was modified to make the store front. I simply cut off the bottom section and made the store windows and front door. I also used parts from the same molds to make the building with the complex roof in the second picture.

Sure the roofs will all have the same texture and the window opening might all look uniform, but shucks, "It's a small town and we only have one carpenter, he only knows of one way to build things"

YES! will also admit it is fun. I have a mold curing right now, I cast some components from a disposable cigarette lighter and the gears from an old alarm clock. You would be surprised how much the thumb wheels look like lumber mill saw blades and how the flint wheel looks like a cog from a steam donkey. (These tips came from the same club member who modeled the buildings in my first picture)

Will try and answer a few of your questions about making the molds. They are fairly durable and I expect to get many parts from them. I am not looking to make duplicates of the same building but rather looking for a way to get more structure parts. Other than DPM and Grandt Line, there are not too many building components out there for us "N" scalers. Cutting window and door openings in textured styrene sheet stock is no small job. A good example is the "Gruber store" from above. Here I made two walls; one side and one back. Both side are identical castings and a casting of the back wall was modified to make the store front. I simply cut off the bottom section and made the store windows and front door. I also used parts from the same molds to make the building with the complex roof in the second picture.

Sure the roofs will all have the same texture and the window opening might all look uniform, but shucks, "It's a small town and we only have one carpenter, he only knows of one way to build things"

YES! will also admit it is fun. I have a mold curing right now, I cast some components from a disposable cigarette lighter and the gears from an old alarm clock. You would be surprised how much the thumb wheels look like lumber mill saw blades and how the flint wheel looks like a cog from a steam donkey. (These tips came from the same club member who modeled the buildings in my first picture)

Very nice Bill. Thanks for sharing this on-going project for us and hope to see more soon!

Matt-Hershey, Pa.

Matt-Hershey, Pa.

AArtwmich:

One of our club members demonstrated some molding last week. He needed some stone walls and the manufacturer has stopped making them. He started with a rubber mould, but that was too floppy.

He found another type of moulding compound that was rather expensive but RE-USABLE. It melts at oven temperature. He had it in a wood frame, but when he's done, he'll melt it and make a different mould.

And some people make their own masters for parts they need a bunch of.

One of our club members demonstrated some molding last week. He needed some stone walls and the manufacturer has stopped making them. He started with a rubber mould, but that was too floppy.

He found another type of moulding compound that was rather expensive but RE-USABLE. It melts at oven temperature. He had it in a wood frame, but when he's done, he'll melt it and make a different mould.

And some people make their own masters for parts they need a bunch of.

Hi Bill.

One of my old landlords fathers used to work at that plant in the '50's. He was stuck there during the flood of '55. Told me his car ended up in Seymour. If my memory sevres me correct, I think it was the "Dupont" rubber plant at the time. Used to make soles for sneakers.

One of my old landlords fathers used to work at that plant in the '50's. He was stuck there during the flood of '55. Told me his car ended up in Seymour. If my memory sevres me correct, I think it was the "Dupont" rubber plant at the time. Used to make soles for sneakers.

Hi eightyeight,

I'm not sure, I do not know the later history of the factory, it may have been owned by Dupont during the fifties. The pictures we are working to, show it only as the "Beacon Falls Rubber Shoe Factory". That is painted very predomently on both towers and we are working on getting the decals printed. You are right, that was a bad flood in '55. Following that flood, the Army Corps of Engineers built damns on the Naugatuck to prevent future reoccurances.

I'm not sure, I do not know the later history of the factory, it may have been owned by Dupont during the fifties. The pictures we are working to, show it only as the "Beacon Falls Rubber Shoe Factory". That is painted very predomently on both towers and we are working on getting the decals printed. You are right, that was a bad flood in '55. Following that flood, the Army Corps of Engineers built damns on the Naugatuck to prevent future reoccurances.

Great modeling, Bill P.

I know exactly what you mean about mold making. I think it's about the greatest development there is for scratch builders, and it's downright fun to produce your own parts. I was amazed at how easy it was to get perfect parts the first time I tried it.

Bill S

I know exactly what you mean about mold making. I think it's about the greatest development there is for scratch builders, and it's downright fun to produce your own parts. I was amazed at how easy it was to get perfect parts the first time I tried it.

Bill S

Bill I found this thread thru a search and was wondering how do you secure the originals to the pour box so that the rtv doesn't get under them?

Nice scratchbuilding Bill. I have only made rock molds so doing stuff like this looks interesting. Thanks for the info.

Well done Bill P

I have to get into doing that. I think those models are very well done.

Now I wonder if I can mold those castings for traction ends out of a plastic or resin???

What do you think Bill??

I have to get into doing that. I think those models are very well done.

Now I wonder if I can mold those castings for traction ends out of a plastic or resin???

What do you think Bill??