I haven't updated my passenger car thread this week...because I've switched back to my Barney & Smith Boxcar. Three weeks ago my copy of Ron Rudnick's DSP&P modeler's guide arrived (30+ pages of drawings and explanations for freight cars!) I immediately started a B&S boxcar for various reasons...including that my wife's family lives in Dayton...which once was home to the Barney & Smith Car Co. I worked on this car for 5 evenings/weekend days...and then I switched to my passenger car project while waiting for super glue...I decided on tuesday night of this week that I could find a way around super glue...and her she is...

The South Park's first cars were built by the Hallack Brothers in Denver...possibly from a Jackson & Sharp kit...this included 5 boxcars...500-504. 505-511 were occupied by the first Tiffany Reefers...the second batch of Tiffany's are available commercially in every scale...HOn3, Sn3, On3, 1:24, 1:22.5, 1:20.3, maybe Nn3, etc...they are probably the most famous of all narrow gauge cars...back to the story...the next known set of cars were 25 cars...some built by Barney & Smith...so by the South Park using B&S parts. This was 1878. These cars were 26' long, 7'6" wide, and had a capacity of 12tons. They rode on swing beam trucks. They were probably number 515ish to 529ish

Commercially, these have never been offered. Most of the hardware can be purchased from Coronado Scale Models & Grandt Line. The proper trucks and couplers are only available from Coronado. The only commercial parts that I intend to use are NBW castings, brake gear (maybe), and couplers (the proper link & pin). I will be dressing it for 1884 (near the end of its life)...so it will have Westinghouse air brakes as the South Park converted in 1883.

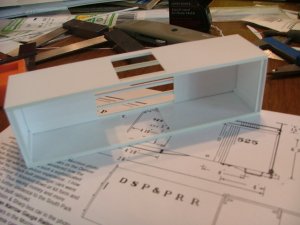

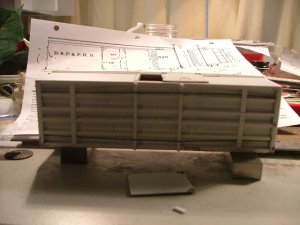

First I built the underframe...and then I built some stiffeners. to support the sides. I used plain styrene sheets for the the flooring...but leaving a hole in the center. I glued them in early to keep the frame straight...and I left the hole to detail the visible portion of the interior.

The sides are from plain scribed siding which I cut on a paper cutter.

I then added 1x12's to fill the gap in the center of the car that was visible from the door...and scraps to fill the rest of the hole. I notched the center of each 1x12 and applied a layer of 1x6s to make it sort of look like ship lap flooring. I also added so scribed siding to the interior to give the appearance of a finished car (this was a mistake...it should be framing...not siding...but I was feeling lazy...and I was watching football).

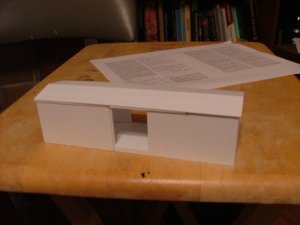

I then added the fascia boards to the sides and but out the fascia for the ends. I glued guide blocks to the end fascia boards...and attached some lengthwise roof supports...in part to allow me to remove the roof during construction.

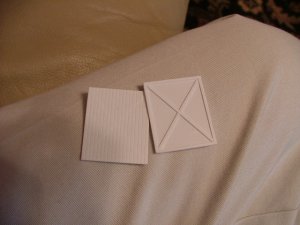

Next I built the doors using 1" thick scribed siding and 1x2 or 3 bracing.

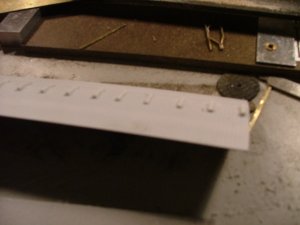

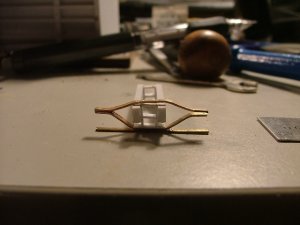

I then decided to try my hand...with inspiration from Bernard's awesome brass hardware...to build some of my own hardware. I cut out the four door hangers from 0.005" thick brass. (yes, I am using a saw on our dining room table...and the wifey took the photo). As you can see...they are tiny.

The South Park's first cars were built by the Hallack Brothers in Denver...possibly from a Jackson & Sharp kit...this included 5 boxcars...500-504. 505-511 were occupied by the first Tiffany Reefers...the second batch of Tiffany's are available commercially in every scale...HOn3, Sn3, On3, 1:24, 1:22.5, 1:20.3, maybe Nn3, etc...they are probably the most famous of all narrow gauge cars...back to the story...the next known set of cars were 25 cars...some built by Barney & Smith...so by the South Park using B&S parts. This was 1878. These cars were 26' long, 7'6" wide, and had a capacity of 12tons. They rode on swing beam trucks. They were probably number 515ish to 529ish

Commercially, these have never been offered. Most of the hardware can be purchased from Coronado Scale Models & Grandt Line. The proper trucks and couplers are only available from Coronado. The only commercial parts that I intend to use are NBW castings, brake gear (maybe), and couplers (the proper link & pin). I will be dressing it for 1884 (near the end of its life)...so it will have Westinghouse air brakes as the South Park converted in 1883.

First I built the underframe...and then I built some stiffeners. to support the sides. I used plain styrene sheets for the the flooring...but leaving a hole in the center. I glued them in early to keep the frame straight...and I left the hole to detail the visible portion of the interior.

The sides are from plain scribed siding which I cut on a paper cutter.

I then added 1x12's to fill the gap in the center of the car that was visible from the door...and scraps to fill the rest of the hole. I notched the center of each 1x12 and applied a layer of 1x6s to make it sort of look like ship lap flooring. I also added so scribed siding to the interior to give the appearance of a finished car (this was a mistake...it should be framing...not siding...but I was feeling lazy...and I was watching football).

I then added the fascia boards to the sides and but out the fascia for the ends. I glued guide blocks to the end fascia boards...and attached some lengthwise roof supports...in part to allow me to remove the roof during construction.

Next I built the doors using 1" thick scribed siding and 1x2 or 3 bracing.

I then decided to try my hand...with inspiration from Bernard's awesome brass hardware...to build some of my own hardware. I cut out the four door hangers from 0.005" thick brass. (yes, I am using a saw on our dining room table...and the wifey took the photo). As you can see...they are tiny.